Overview

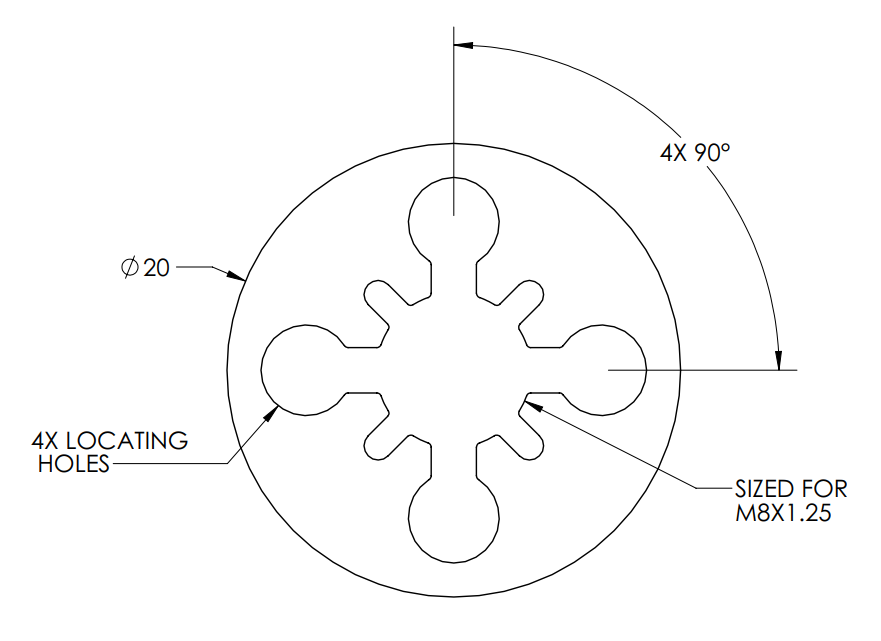

Featuring M8 x 1.25 mm tappable ends, a lightweight design, and anti-rotation holes, the round extrusion is launching alongside a new part ecosystem that will let you build entirely new types of Vention assemblies.

Round extrusion components are compatible with all existing Vention parts. Combine them with 45 x 45 mm, 45 x 90 mm, and 90 x 90 mm T-slot profiles to create mounting arms, custom end-of-arm tooling, rotary systems, and ergonomic handles.

Round extrusion applications

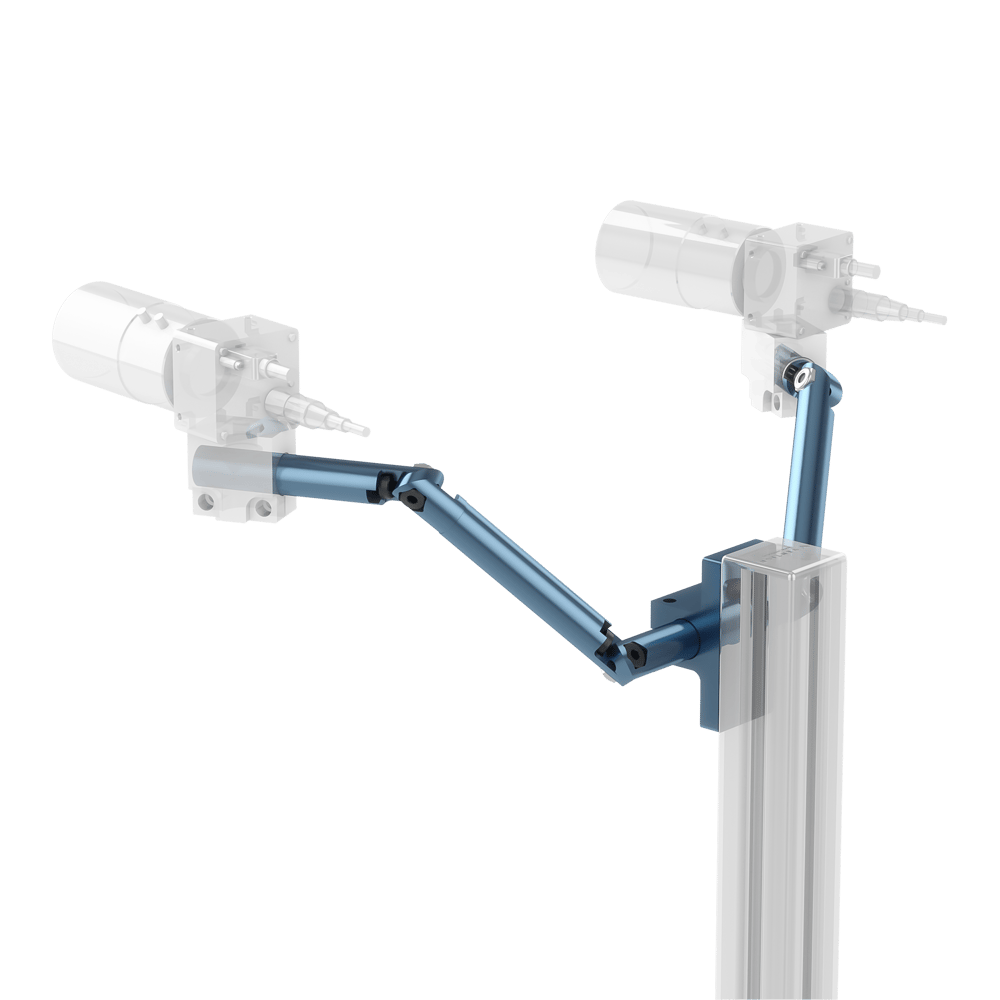

Mounting arms

Round extrusions provide a flexible and customizable solution for mounting cameras, scanners, or other sensors. Lightweight and low-profile, these extrusions are perfect for mounting parts at different angles or in tighter spaces.

Two cameras, mounted with round extrusions on adjustable arms. |

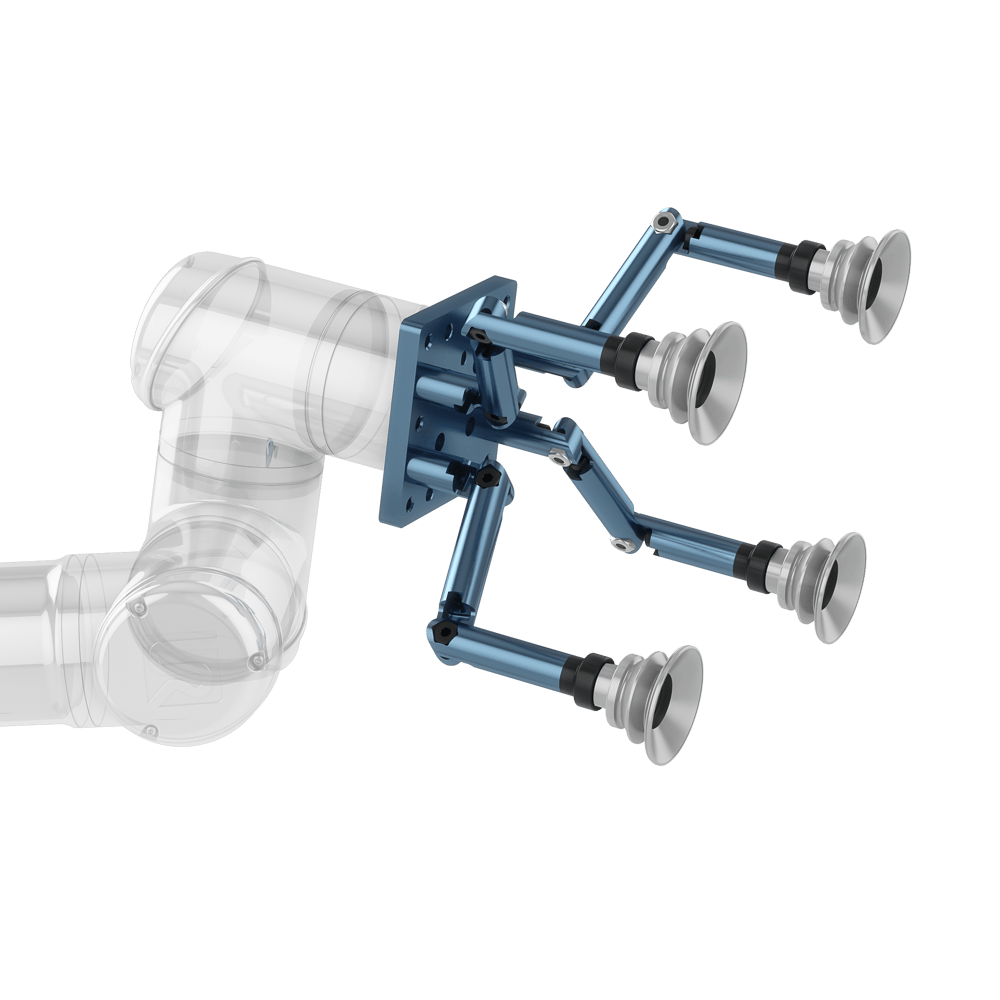

Custom end-of-arm tooling

The robot’s payload includes the weight of end-of-arm tooling, so keeping weight low is a top priority for custom tooling design. With its low weight and high strength, the new round extrusion ecosystem lets you maximize load capacity.

Vacuum gripper (custom end-of-arm tooling example). |

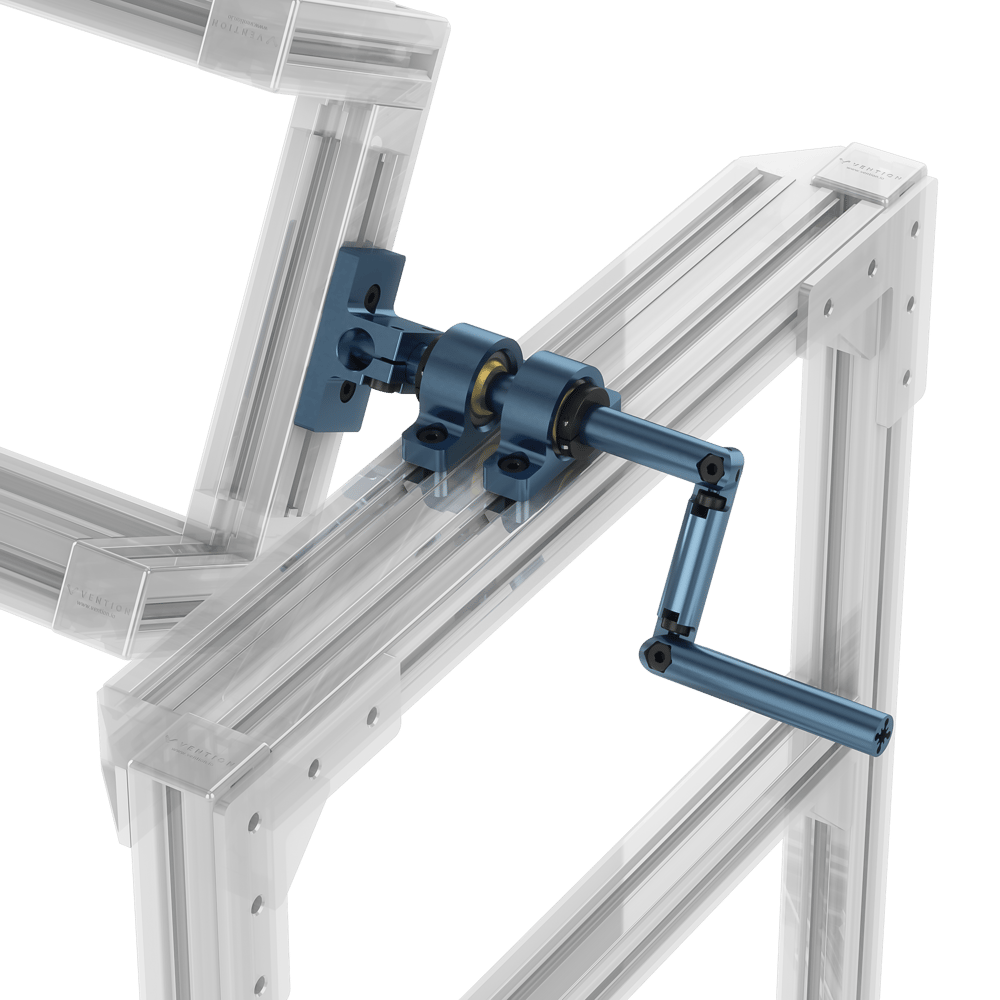

Rotary work stations

Construct rotating assemblies using the round extrusion pillow bearing (MO-BR-007-0001).

These bearings are particularly helpful in applications like assembly jigs that require access on all sides. The self-aligning plastic bushings in each pillow bearing provide a maintenance-free solution.

Rotating assembly supported by two pillow bearings. |

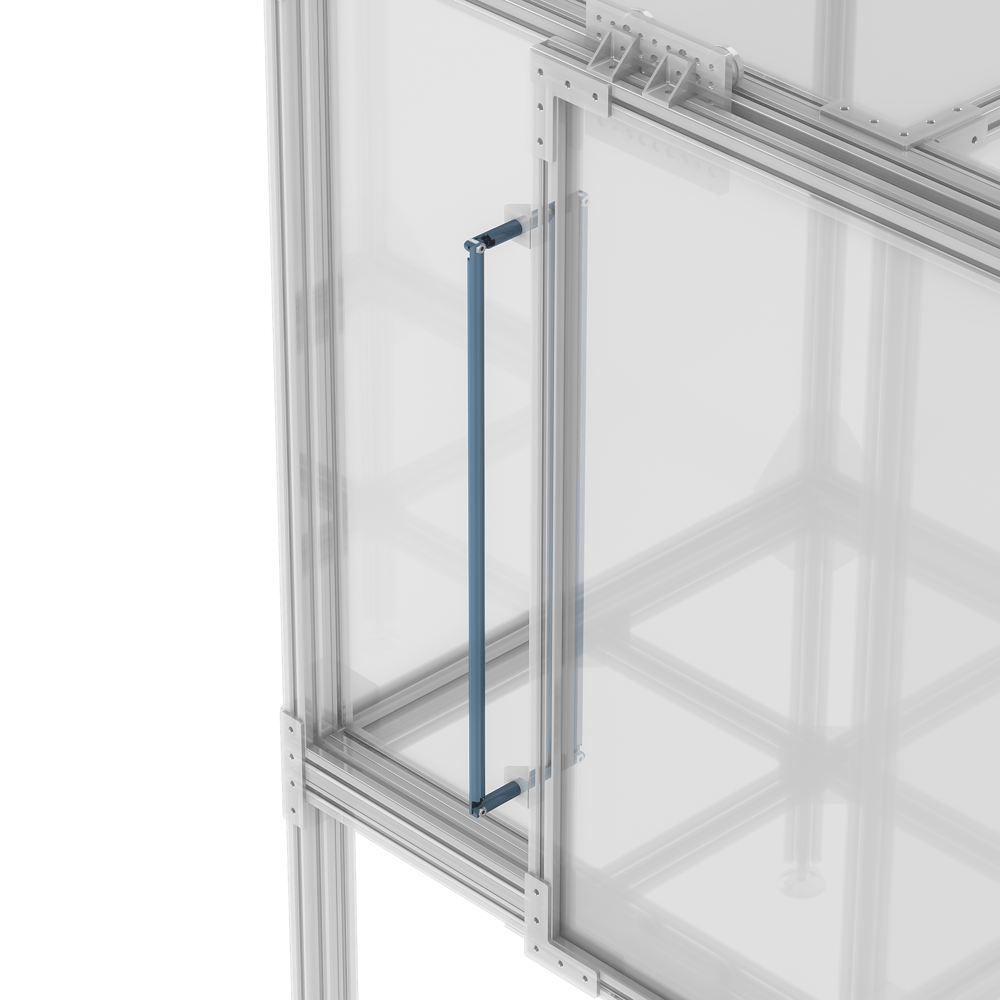

Ergonomic handles

Round extrusions are great in any application where ergonomics are a factor, such as door handles. Mount round extrusions, using their tapped ends, directly onto Vention assembly plates, gussets, and tooling plates.

Sliding door handle composed of three round extrusions linked together. |

Round extrusion ecosystem

A new ecosystem of parts supports the round extrusion, although current parts are also fully compatible.

Round extrusion

Made of strong, lightweight 6005-T5 aluminum, and anodized in Vention blue—like all our extrusions—round extrusions (ST-EXT-008-XXXX) have a tough, wear-resistant finish. They’re easy to attach to standard Vention parts, thanks to a center hole that can be tapped for an M8 bolt.

Round extrusion section. |

Diameter | 20mm |

Material | 6005-T5 |

Yield stress | 240 MPa |

Area moment of inertia | 6469.72 mm4 |

Torsional constant | 10,492 mm4 |

Profile area | 208.47 mm2 |

Weight per 45 mm length | 25 g |

Table 1: round extrusion specifications

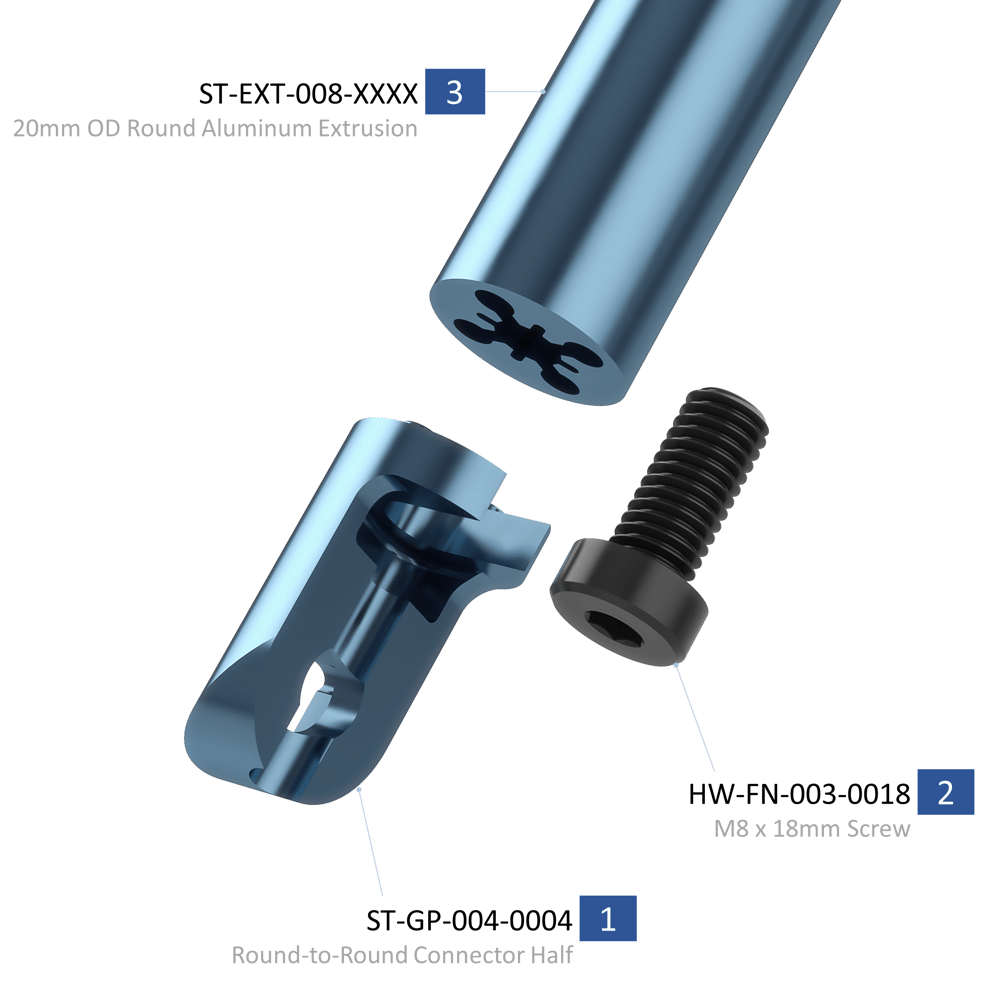

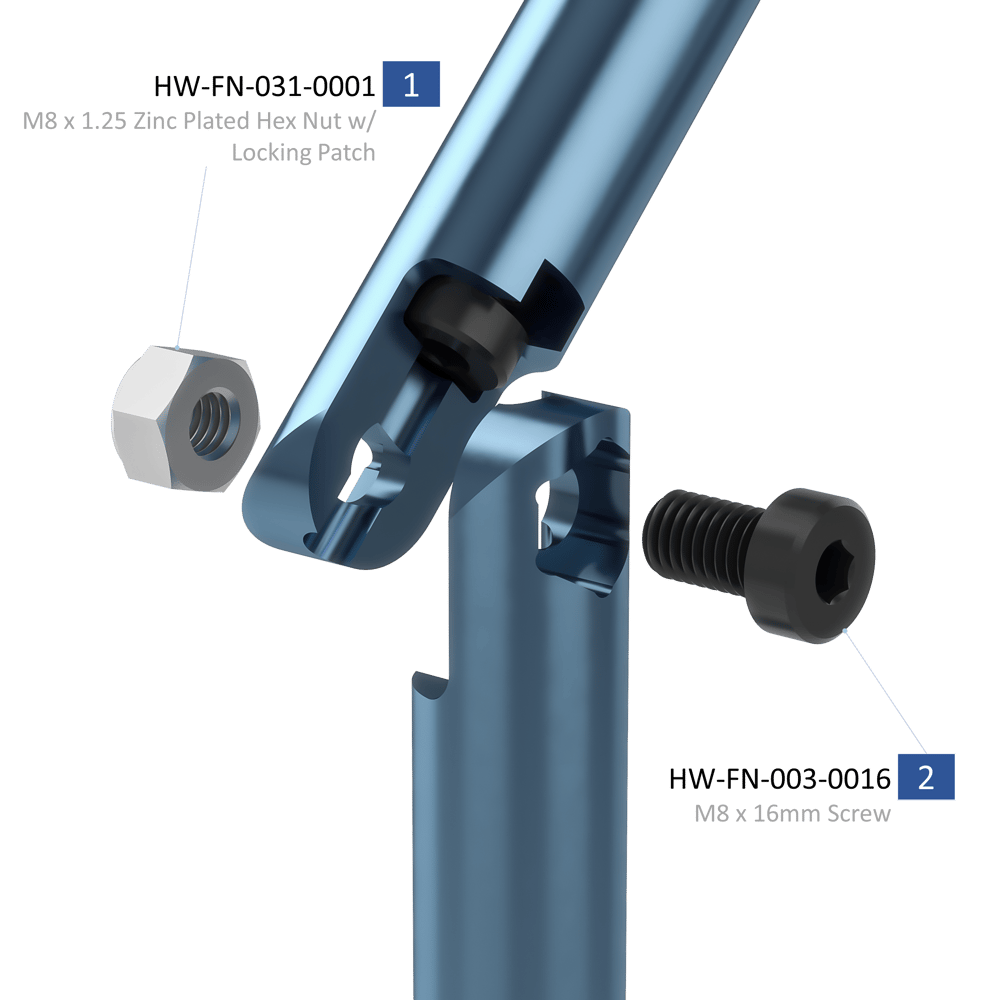

Round-to-round angle connector

Connect two round extrusions together at various angles with the round-to-round angle connector (ST-GP-004-0005). Two pins on each connector half prevent the extrusion from rotating axially—relative to the connector—crucial for a secure connection that won’t come loose.

To connect two round extrusions with the angle connector:

Tap one end of each extrusion.

Attach a connector half to each tapped extrusion end.

Fasten the two connector halves together with one M8 x 16mm Screw (HW-FN-003-0014) screw and one M8 nut (HW-FN-031-0001).

Max axial torque | 15 Nm |

Max joint torque* | 5 Nm |

Connection angle (measured from parallel) | ±75° |

Table 2: round-to-round angle connector specifications

*Ideally, both ends of a round extrusion should be supported. If this is not possible, limit the torque placed on the joint (max 5 Nm) to prevent the joint from slipping. This can be done by keeping the load small or the lever arm short

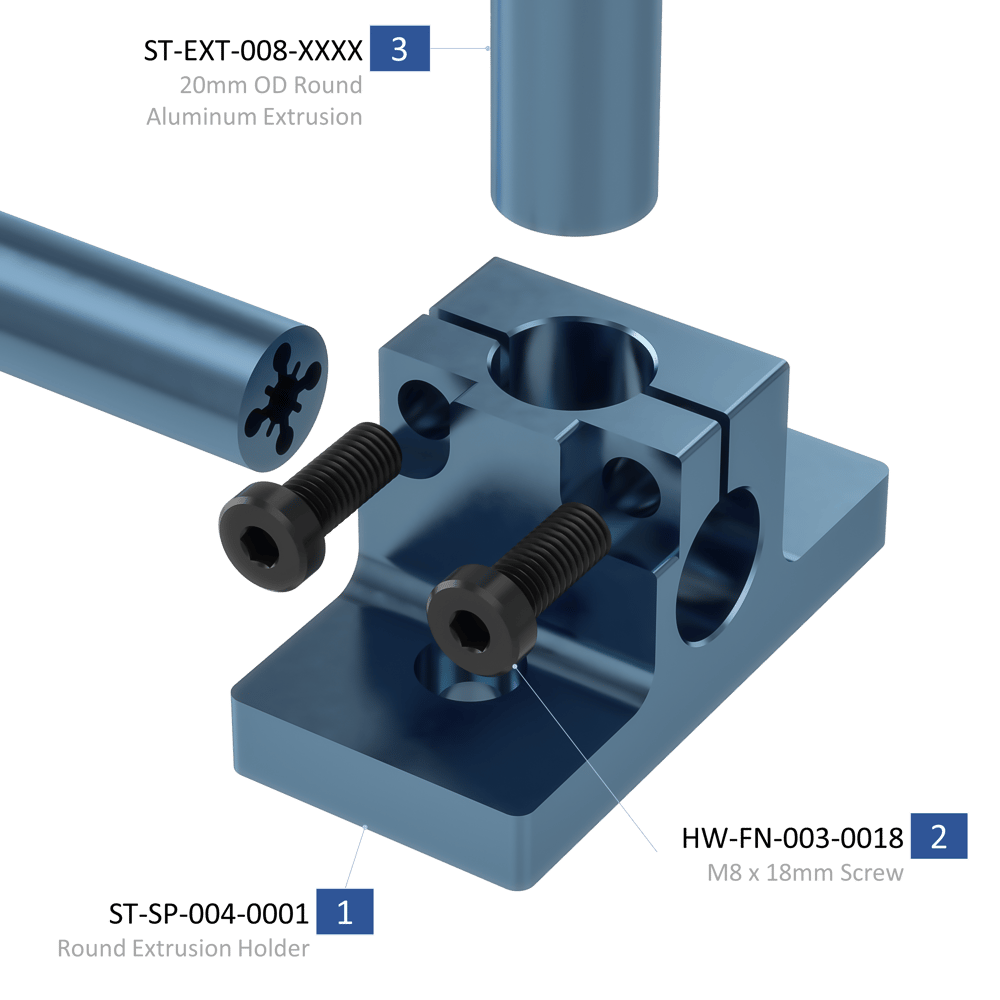

Round extrusion holder

If you need to attach your round extrusion assembly to a square extrusion, such as the Vention 45-mm square extrusion, one solution is the round extrusion holder (ST-SP-004-0001).

It has two mounting options: perpendicular, or parallel to the square extrusion. When mounting perpendicularly, you can use the built-in pin to hold the extrusion in one of four positions.

Round extrusion holder. |

Note: Round extrusion holder will resist a max of 12.5 Nm of torque before slipping.

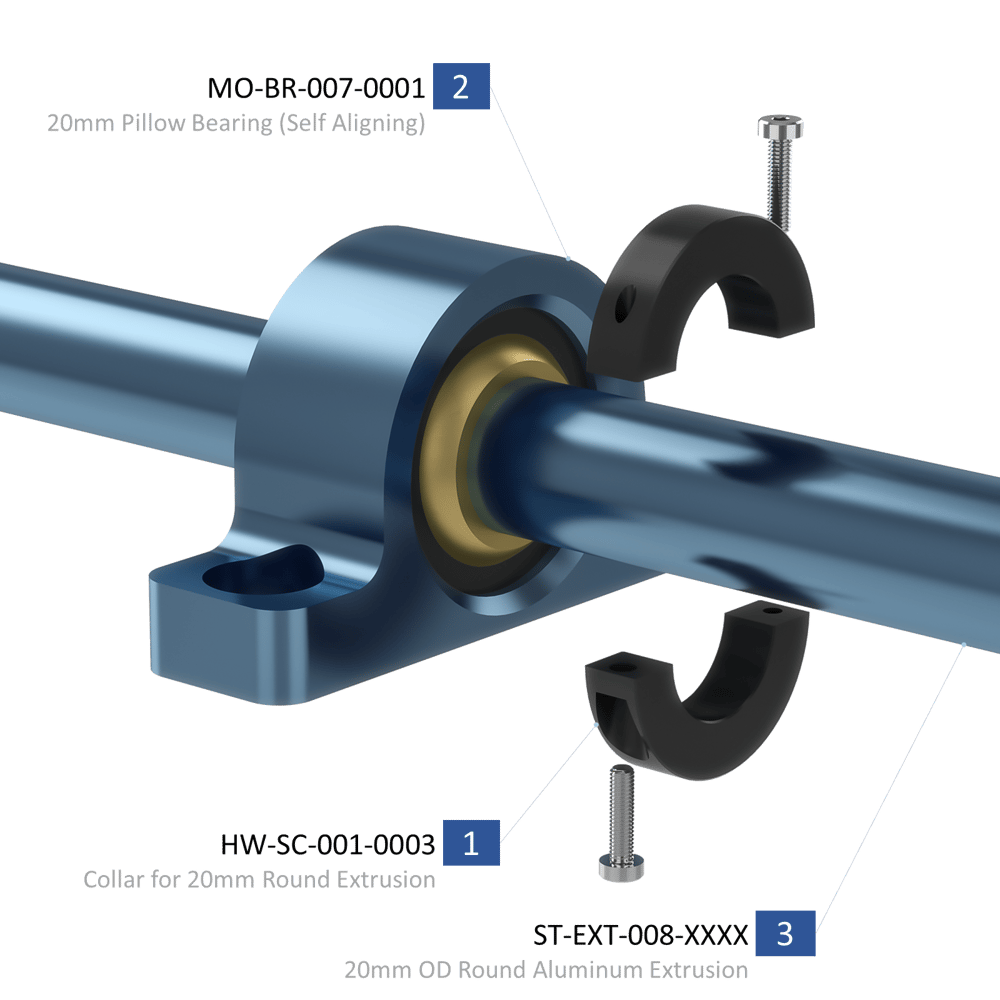

Self-aligning pillow bearing and shaft collar

Round extrusions, with their accompanying pillow bearings and shaft collars, can be used to great effect when designing for rotary applications.

Pillow bearings (MO-BR-007-0001) are self-aligning plastic units that require no additional lubrication. Shaft collars (HW-SC-001-0003) hold the shaft in place axially.

Shaft, bearing and collar assembly. |

Note: Each shaft requires two shaft collars for axial fixing.

Max axial force | 5000 N |

Max radial force | 10000 N |

Max rotational speed | 2880 deg/s |

Max angular misalignment permitted | ±20° |

Table 3: pillow bearing specifications