Extrusion Profiles

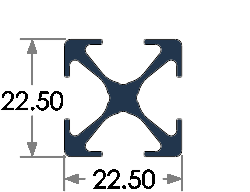

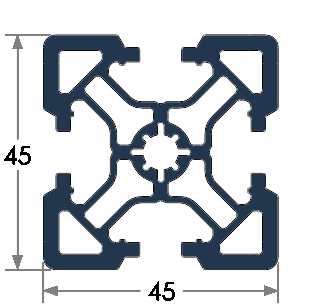

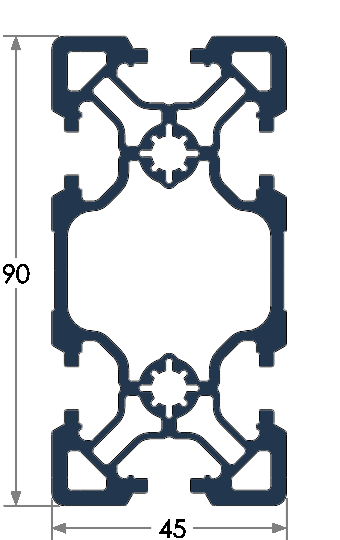

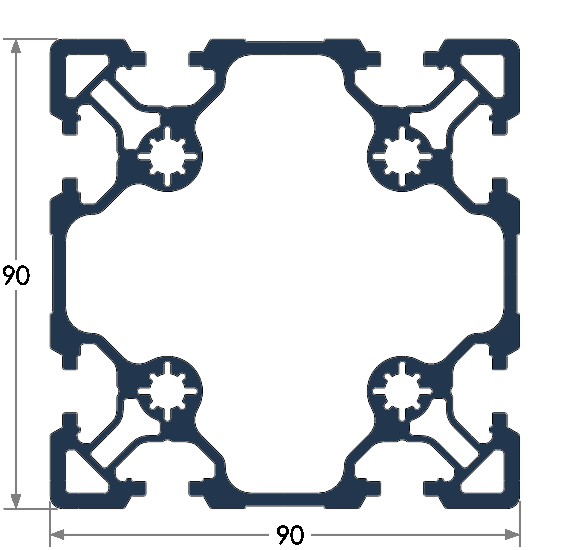

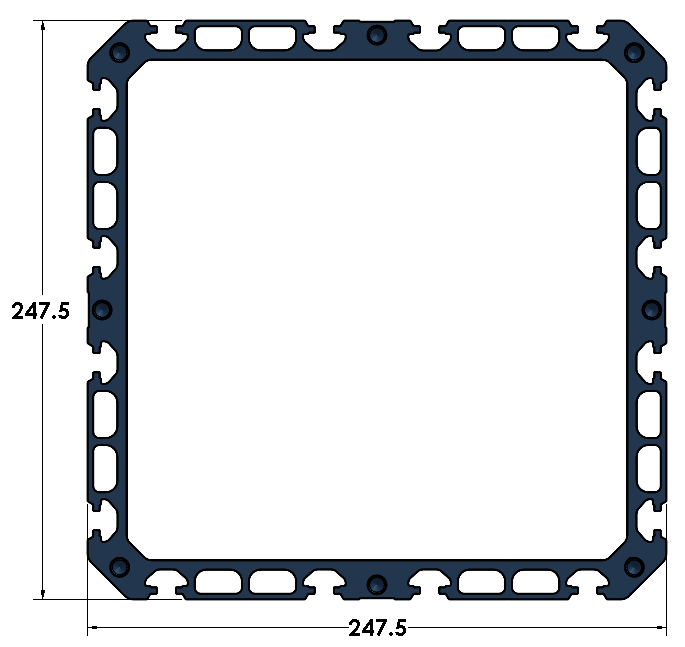

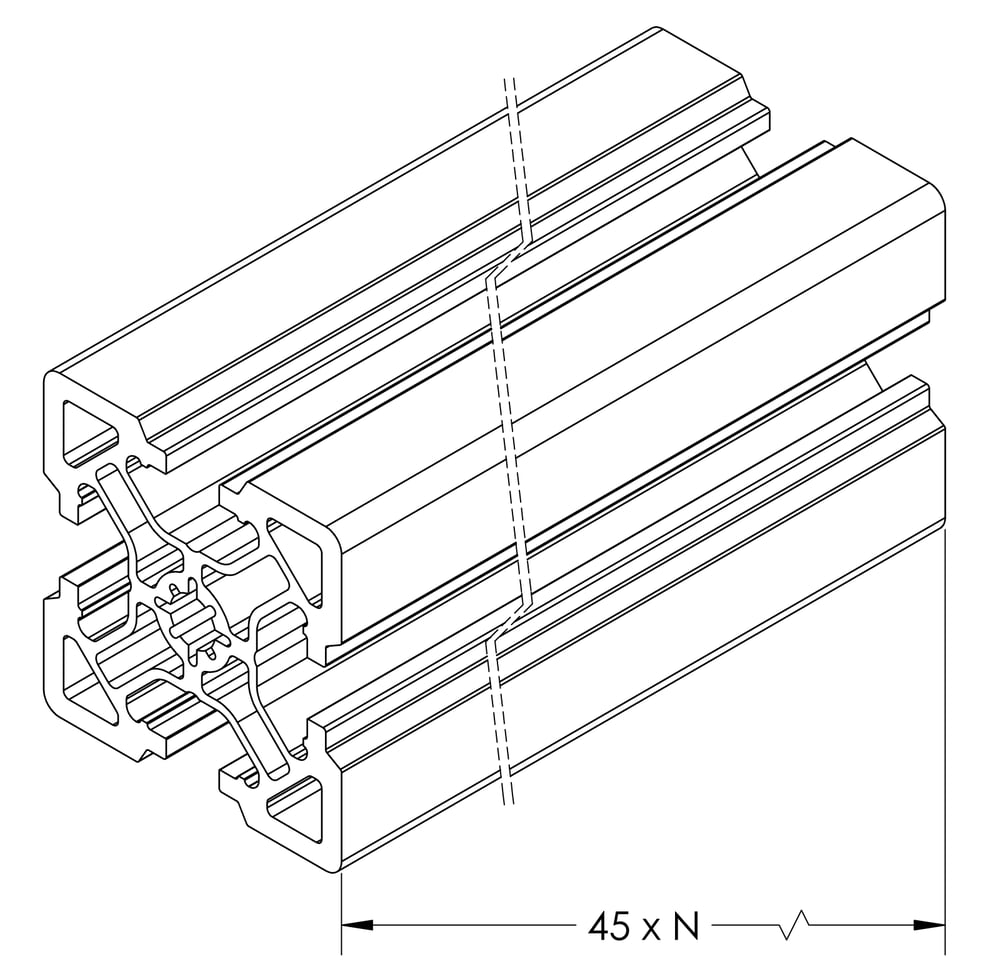

Four extrusion profiles form the core of the Vention architecture: 22.5 x 22.5 mm, 45 x 45 mm, 45 x 90 mm, 90 x 90 mm, and 247.5 x 247.5 mm. These profiles are optimized for best-in-class ratios of the moment of inertia per unit of surface area.

For more information, on the moment area of inertia of these extrusions and other more technical details, see our document on Designing with T-Slot Aluminum Extrusions.

A T-shaped slot spans the length of each extrusion. This slot can accept an M8-1.25 T-nut by either sliding the T-nut in from the end or inserting it from the side. Because all Vention extrusions use the same M8 T-nuts, profiles of various sizes can be combined together to create custom assemblies. Vention extrusions are cut to size to the nearest 45 mm. Their lengths range from 45 mm to 1530 mm for the 22.5 x 22.5 mm profile, 45 mm to 2295 mm for the 45 x 45 mm profile, 45 mm to 3330 mm for 45 x90 mm, and 90 x90 mm profiles, and 1845 mm to 3330 mm for 247.5 x 247.5 mm profiles. All our extrusions are made of 6005-T5 aluminum and are blue-anodized to Vention’s standard. The table below lists all the sizes available for each profile.

Extrusion Length | 22.5 x 22.5 mm | 45 x 45 mm | 45 x 90 mm | 90 x 90 mm | 247.5 x 247.5 mm |

|---|---|---|---|---|---|

45 | ✔ | ✔ | ✔ | ✔ | |

90 | ✔ | ✔ | ✔ | ✔ | |

135 | ✔ | ✔ | ✔ | ✔ | |

180 | ✔ | ✔ | ✔ | ✔ | |

225 | ✔ | ✔ | ✔ | ✔ | |

270 | ✔ | ✔ | ✔ | ✔ | |

315 | ✔ | ✔ | ✔ | ✔ | |

360 | ✔ | ✔ | ✔ | ✔ | |

405 | ✔ | ✔ | ✔ | ✔ | |

450 | ✔ | ✔ | ✔ | ✔ | |

495 | ✔ | ✔ | ✔ | ✔ | |

540 | ✔ | ✔ | ✔ | ✔ | |

585 | ✔ | ✔ | ✔ | ✔ | |

630 | ✔ | ✔ | ✔ | ✔ | |

675 | ✔ | ✔ | ✔ | ✔ | |

720 | ✔ | ✔ | ✔ | ✔ | |

765 | ✔ | ✔ | ✔ | ✔ | |

810 | ✔ | ✔ | ✔ | ✔ | |

855 | ✔ | ✔ | ✔ | ✔ | |

900 | ✔ | ✔ | ✔ | ✔ | |

945 | ✔ | ✔ | ✔ | ✔ | |

990 | ✔ | ✔ | ✔ | ✔ | |

1035 | ✔ | ✔ | ✔ | ✔ | |

1080 | ✔ | ✔ | ✔ | ✔ | |

1125 | ✔ | ✔ | ✔ | ✔ | |

1170 | ✔ | ✔ | ✔ | ✔ | |

1215 | ✔ | ✔ | ✔ | ✔ | |

1260 | ✔ | ✔ | ✔ | ✔ | |

1305 | ✔ | ✔ | ✔ | ✔ | |

1350 | ✔ | ✔ | ✔ | ✔ | |

1395 | ✔ | ✔ | ✔ | ✔ | |

1440 | ✔ | ✔ | ✔ | ✔ | |

1485 | ✔ | ✔ | ✔ | ✔ | |

1530 | ✔ | ✔ | ✔ | ✔ | |

1620 | ✔ | ✔ | ✔ | ||

1710 | ✔ | ✔ | ✔ | ||

1800 | ✔ | ✔ | ✔ | ||

1845 | ✔ | ✔ | ✔ | ✔ | |

1980 | ✔ | ✔ | ✔ | ||

2115 | ✔ | ✔ | ✔ | ||

2295 | ✔ | ✔ | ✔ | ✔ | |

2610 | ✔ | ✔ | |||

2970 | ✔ | ✔ | |||

3330 | ✔ | ✔ | ✔ |

Extrusion Interfaces

Parts connecting to extrusions can rest flat on the exterior side surfaces of the extrusion, or can be mounted by threading the hole at the end of the extrusion. The extrusion ends can be threaded with a M8-1.25 tap. You can also self-thread the extrusion ends using a M8-1.25 screw, if taps are not readily available.

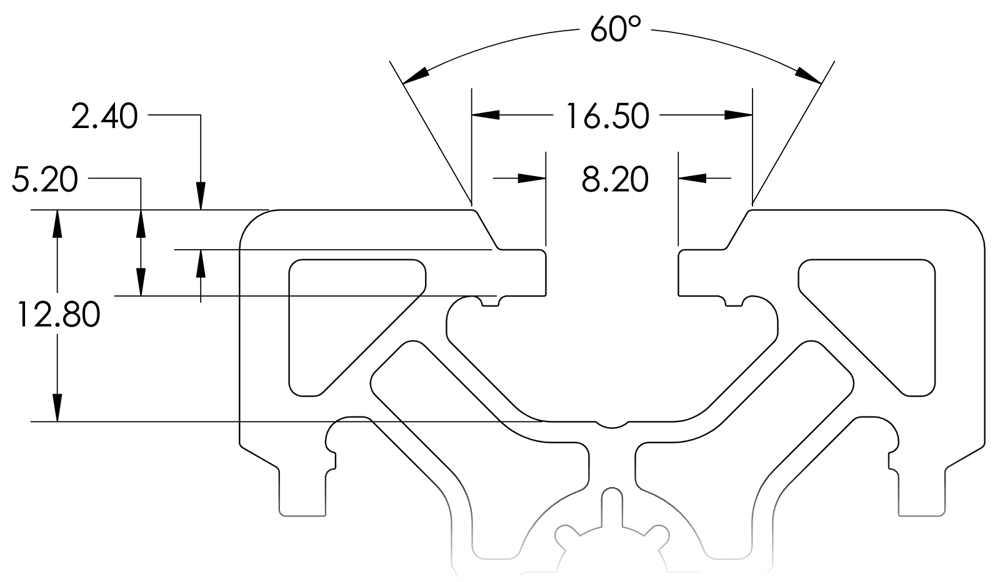

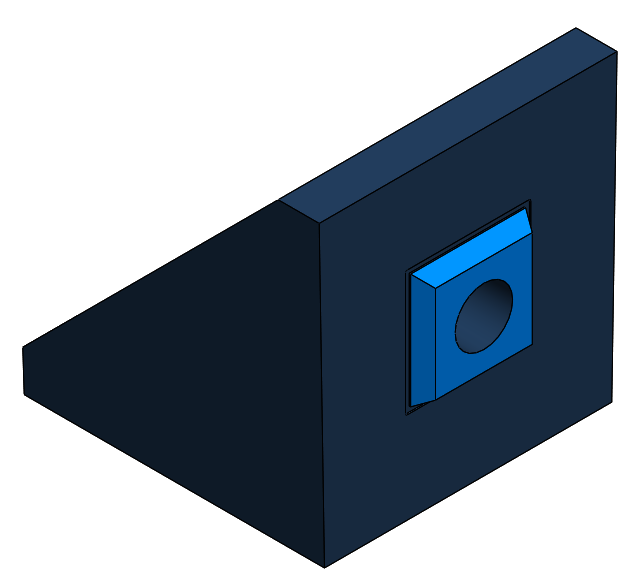

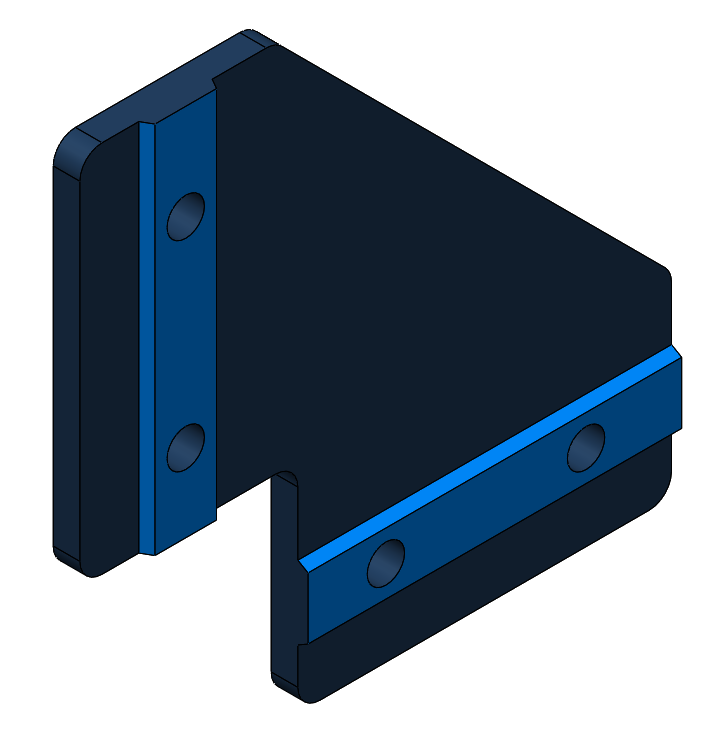

When connecting parts to extrusions, the V-shaped groove can provide increased rigidity and precision, and can prevent part rotation even when using a single screw. A truncated pyramid boss, also referred to as a high precision feature, may be used if parts need to be mounted in more than one orientation while using the V-shaped feature.

Vention’s V-shaped groove feature is patent pending (USPTO #15/798,862). Please contact Vention to discuss a licensing agreement if you are interested in manufacturing industrial components integrating this feature. The groove dimensions are shown below for reference.

|

|

|

Fasteners

Vention’s three larger extrusion profiles have a groove depth of 12.80 mm (measured from the top surface of the extrusion). Since Vention’s standard mounting plates are 6 mm thick, the standard fastener is an 18 mm long M8-1.25 screw, with a low-profile socket head. Our system is designed such that all screws can be tightened using a 5 mm Allen key. Given that Vention users only use hand tools to assemble, the standard torque for fasteners is set to 13 Nm.

At this torque specification, an aluminum assembly plate connected to an aluminum extrusion can support up to 2.1 kN per fastener in a pure friction joint. It can also support pull-out loads of up to 16.7 kN before the extrusion deforms. Note that these values should be adjusted to take into account proper security measures.

All Vention screws are conversion-coated with black oxide. Through rigorous vibration testing, we have determined that black oxide-coated screws have significantly better anti-vibration properties than zinc-plated screws.

Below is a table of all standard screws and their uses. Note that all Vention screws use a low-profile socket head.

Thread | Length (mm) | Use |

|---|---|---|

M8 | 10 | Mounting sheet-metal parts and MachineMotion on the 22.5 x 22.5 mm profile |

12 | Mounting assembly plates on the 22.5 x 22.5 mm profile and attaching caster wheels to plates | |

16 | Mounting sheet-metal parts and MachineMotion on the 45 x 45 mm, 45 x 90 mm, 90 x 90 mm and 247.5 x 247.5 mm profiles | |

18 | Mounting assembly plates on the 45 x 45 mm, 45 x 90 mm, 90 x 90 mm and 247.5 x 247.5 mm profiles | |

25 | Mounting heavy-duty hinges on the sides of the 45 x 45 mm, 45 x 90 mm, 90 x 90 mm and 247.5 x 247.5 mm profiles | |

30 | Mounting thicker robot plates on the 45 x 45 mm, 45 x 90 mm, 90 x 90 mm and 247.5 x 247.5 mm profiles | |

55 | Mounting assembly plates, hinges, in-line connectors, and actuator blocks on the tapped end of an extrusion | |

80 | Mounting heavy-duty hinges on the tapped end of an extrusion | |

M6 | 20 | Mounting all Vention powertrain components compatible with NEMA 34 stepper motors |

Part Geometry

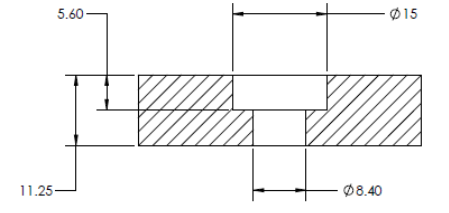

The standard Vention plate thickness is 6 mm, with the next available thickness being 11.25 mm. |

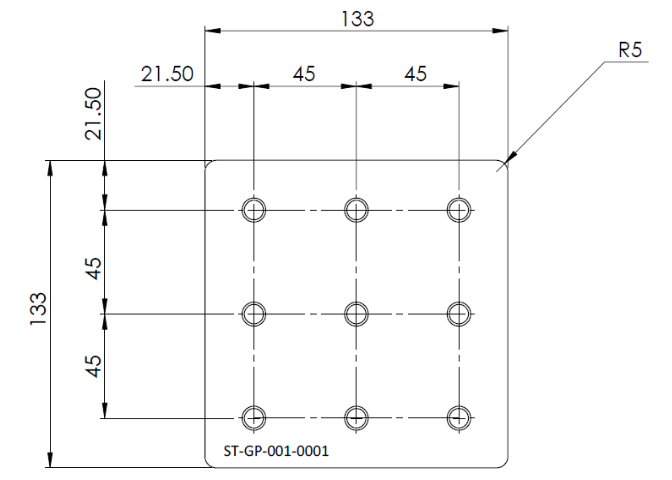

Bolt Patterns, Hole Sizes, and Counterbores

All 6 mm thick parts have 8.4 mm through-holes located at a 45 mm distance from each other, with the first mounting hole being located 21.5 mm from the edge of the plate (see drawing above). |

Wheels, Leveling Feet, and Floor Anchors

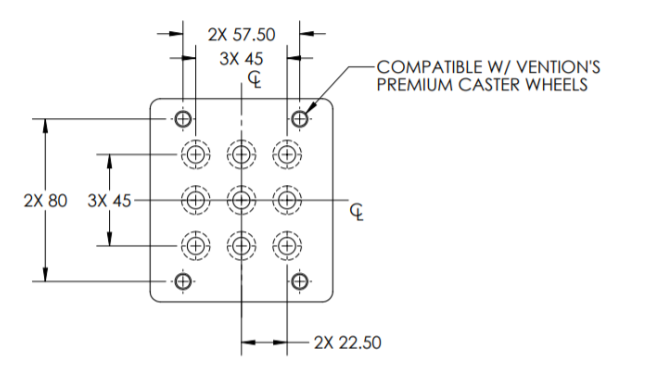

Swivel and caster wheels fit our extrusions using standard 11.25 mm thick plates. These mounting plates must have a Vention interval bolt pattern, and the bolt pattern must accommodate the swivel or caster wheel. |

Each leveling foot includes a M8-1.25 threaded stud such that the foot can be mounted on the tapped end of an extrusion. |

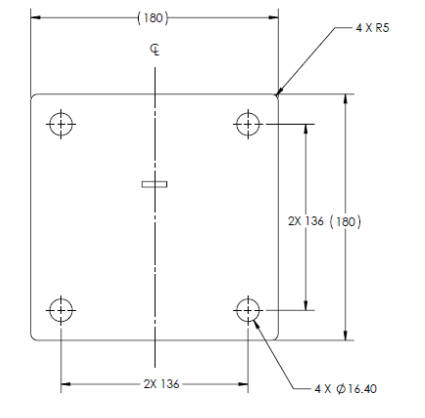

Each floor anchor has four 16.4 mm clearance holes to accommodate standard half-inch concrete anchor screws. Floor anchors also feature two layers of screws at 45 mm intervals, to maximize the number of mounting configurations. |

Part Materials

The table below lists standard materials for Vention parts.

Material | Type | Use |

|---|---|---|

Aluminum | 5052-H32 | Non-structural aluminum sheet-metal parts |

6061-T6 | Assembly plates, actuator components, robot plates, and general machined parts | |

6005-T5 | Extrusions (45 x 45 mm, 45 x 90 mm, 90 x90 mm, Table Top and Round Extrusions) | |

6063-T5 | Extrusions (22.5 x 22.5 mm, 247.5 x 247.5 mm) | |

Steel | 1010 | Floor anchors and non-structural steel sheet-metal parts |

1018 | Structural steel sheet-metal parts | |

1045 | Gear rack for Rack and Pinion assembly | |

304 SS | Power transmission shafts |

Part Colors

Vention parts come in three colors.

Color | RAL Code | Use |

|---|---|---|

Vention Blue | 5011 | Machined parts and extrusions |

Graphite Grey | 7024 | Injection-molded plastic parts |

Graphite Black | 9011 | Powder-coated steel parts and power transmission components |

Logo Placement and Dimensions

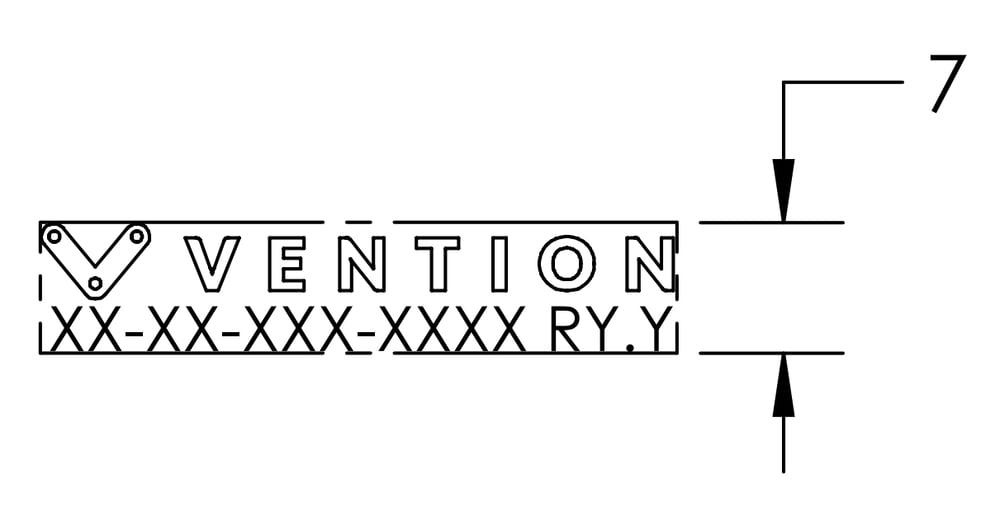

All Vention hardware features the Vention logo and part number engraved into the lower left corner (when that corner is available). On larger assemblies, the assembly part number must be properly displayed and all children part numbers for individual components must be hidden when fully assembled.

The Vention logo and part number must be 7 mm tall. The logo consists of 64% of the total height and the part number consists of the remaining 36%.

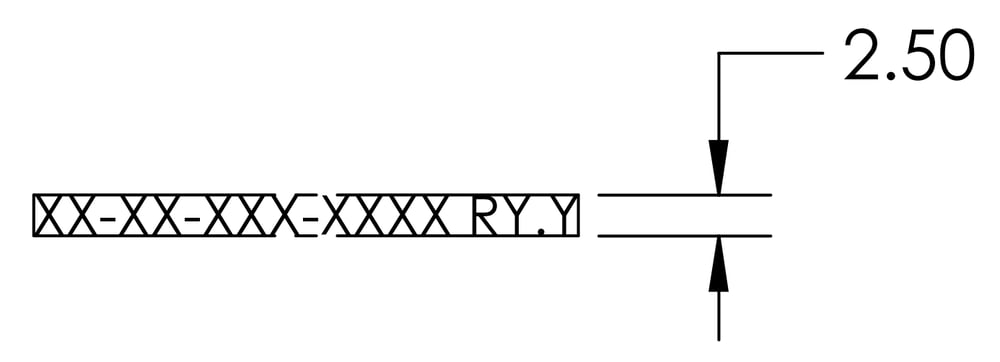

Some children parts of larger assemblies only feature the part number and not the Vention logo. The part number alone should be 2.5 mm tall when possible. The font used for all part numbers is Inter.

Additionally, all robot plates with a thickness of at least 11.25 mm must have the Vention logo and website with a total height of 6.5 mm.

Please contact us if you require any sketches of the Vention Logo.

Aluminum Parts (Anodization)

All Vention parts are corrosion-resistant. Aluminum parts require a standard sulfuric blue anodization. Prior to anodization, Vention parts receive a uniform shot-peening treatment, which results in a dull orange-peel effect on the surface texture post-anodization. An acid etching is then performed to remove impurities from the part’s surface and ensure a uniform, matte surface finish. Finally, parts are treated with a standard sulfuric blue MIL-A-8625 Type II anodization in color RAL 5011.

Steel Parts

Steel parts are plated in clear zinc (chromate conversion, trivalent chromium) or powder-coated. Surfaces are finished in a medium sandblast texture equivalent to a D2 SPI finish or 26-32 Ra roughness.

All steel shafts are hardened to HRC 60. They may also be chrome-plated if required for the application.

Motor Configuration

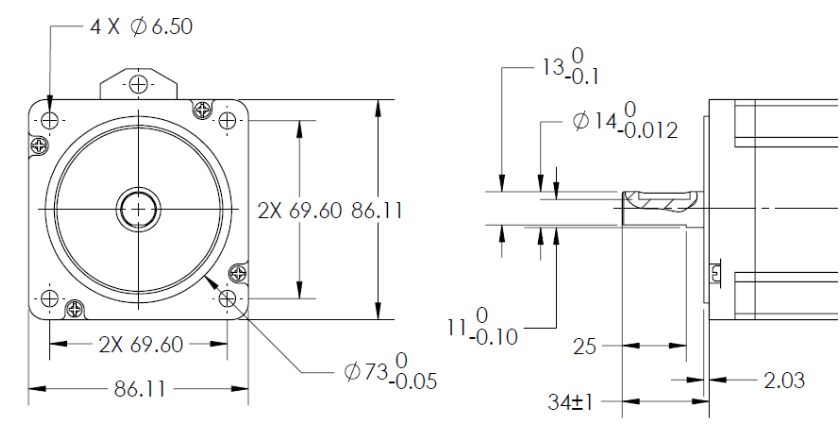

Vention’s MachineMotion controller supports NEMA 34 standard stepper motors. The shaft configuration shown below guarantees a proper fit with all Vention actuators.

MachineMotion Sensors, Inputs, and Outputs

Vention’s automation controller features industry-standard M12 connectors for all external sensory inputs. The drive sensor and security connections include four-pin connectors, whereas the auxiliary inputs and pendant connection include eight pin connectors.