MachineMotion V2 Path Following Interface

Overview

MachineMotion’s path following interface enables Vention machines to execute 3D trajectories. It is modelled after standard CNC machine interfaces and can handle a variety of commands. To perform path following with MachineMotion, a user will need:

MachineMotion hardware V2B3 or newer [see how to find this in Method 3 - MachineMotion Pendant Step 3]

MachineMotion software v2.6.0 or newer [see how to find this in Method 3 - MachineMotion Pendant Step 3]

A g-code file compatible with [Vention’s g-code interface]

A python script that loads and starts the g-code file (see Python Example at the bottom of this page)

The Guide for the MachineApps - Path Following for MachineMotion 1, can be found in the ‘‘Documentation for Previous Releases’’ at the bottom of this page.

Path following on the MachineMotion happens in two steps: g-code parsing and motion streaming. G-code parsing is the process of turning g-code commands into 3D setpoints, while motion streaming is the act of sending those setpoints to relevant drives at a fixed period. Since g-code has a generic syntax that maps to tools and axes, while motion streaming is tied to Vention drives and I/Os, there are three main elements that need to be defined for path following: axis configuration, tool configuration and path parameters. The following sections will show you how to set up and program a MachineMotion, as well as a full description of available g-code commands.

Axis Configuration

Vention’s g-code interface support three axes: X, Y and Z. Each axis may be mapped to a drive on MachineMotion. If using synchronized drives (e.g. two timing belt actuators with gearboxes), the g-code axis must be associated with the parent drive of the Vention axis. For example, in a python script, this is how one would setup their axis configuration for a machine with a synchronized timing belt axis on drives 1 and 2 and a ballscrew axis on drive 3:

# associate with the parent drive

driveAssociation = {"X": 1, "Y": 3}

# Configure the path following mode

mm.configPathMode(driveAssociation)

The mapping between g-code axes and Vention drives is arbitrary; one could assign drive 4 to the X axis and drive 1 to the Y axis.

NOTE: It is important to consider the directions of g-code axes and their effect on the behaviour of the machine. If the machine has an end of arm tool that can collide with a workpiece, ensure that axes home away from the workpiece. And example of this is in CNC routing applications, the Z (vertical) axis should home upwards and away from the workpiece. Axis directions should also be set up to follow the right hand rule to avoid discrepancies between the expected and executed path.

Tool Configuration

G-code programs sometimes make use of one or more tools. These tools can be lasers, pneumatics, routers, etc. On Vention machines, these tools are controlled with digital outputs. Vention’s python interface enables the configuration and control of digital outputs via the DIGITAL_OUTPUT_STATE and TOOL classes:

clockwise = DIGITAL_OUTPUT_STATE(deviceId=1, port=0, value=1)

counterClockwise = DIGITAL_OUTPUT_STATE(1, 1, 1)

tool1 = TOOL(1, clockwise, counterClockwise)

# associate with the parent drive

driveAssociation = {"X": 1, "Y": 3}

# Configure the path following mode

mm.configPathMode(driveAssociation, tool1)

In Vention’s path following interface, a tool consists of a tool number as well as a configuration for clockwise and counterclockwise rotation. Each rotation configuration corresponds the digital IO module’s device ID, port and value that is wired to the desired tool. An arbitrary amount of tools can be defined via the Python API, provided each tool has a unique tool number.

Parser Configuration

Vention’s g-code parser takes only one argument as configuration: the max path acceleration. This corresponds to the maximum rate in mm/s2 at which the output path can accelerate. Below is an example of how to define the max path acceleration:

maxPathAcceleration = 1000 # mm/s^2

mm.setAxisMaxAcceleration(1,1000)

mm.setAxisMaxAcceleration(3,1000)

mm.setAxisMaxSpeed(1,500)

mm.setAxisMaxSpeed(3,500)

# Start Path Following.

mm.startPath(GCODE_STRING, maxPathAcceleration)

NOTE: The max path acceleration, as well as the path speed, is independent from and capped by each drive’s max acceleration and speed. It is good practice to set each relevant drive’s max speed and acceleration in python before entering path following mode

G-Code Interface

Vention’s g-gode interface provides a set of machine instructions that allow a user to smoothly move multiiple axes at once. There exist various different versions of g-code that are offered by industrial manufacturers. Vention’s is based off RS-274-NGC gcode language and LinuxCNC. If using a CAM software to generate g-code, choosing either as a post-processor will ensure that it is compatible with MachineMotion. Vention does not support the entire list of g-code commands provided by RS-274-NGC or LinuxCnc, so some advanced codes (such as custom drilling routines or patterns) may not be recognized. The following section describes the two types of available g-code commands: operational mode commands and movement and tool commands.

Operational Mode Commands

Operational mode commands affect the way that Vention’s g-code parser generates points. They don’t cause motion of axes or tools.

G20: Set Inch Length Units

Format:

G20

Description:

Sets length units to inches. Affects distances and speeds. It is a good idea to include units in the preamble of each g-code file.

Example:

G91 G20

G0 X5 F100 ; X axis will 5 move inches at 100 inches/minute

G21: Set Millimeter Length Units

Format:

G21

Description:

Sets length units to millimeters. Millimeters are the default length unit of the parser. Affects distances and speeds. It is a good idea to include units in the preamble of each g-code file.

Example:

G91 G21

G0 X50 F1000 ; X axis will move 50 mm at 1000 mm/minute

G61: Exact Move Mode

Format:

G61

Description:

Exact path mode, movement exactly as programmed. Moves will slow or stop as needed to reach every programmed point. If two sequential moves are exactly co-linear movement will not stop.

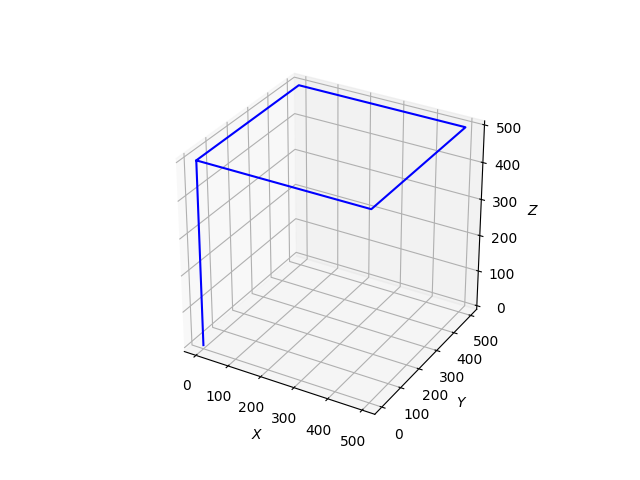

Example:

G91 G21 G61

G0 X500

Y500

X-500

Y-500

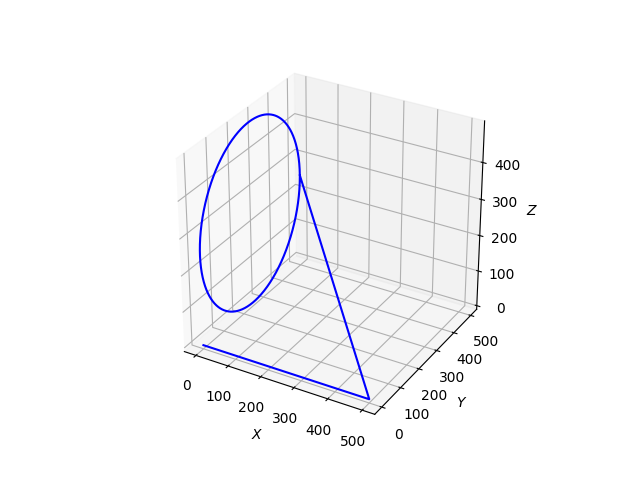

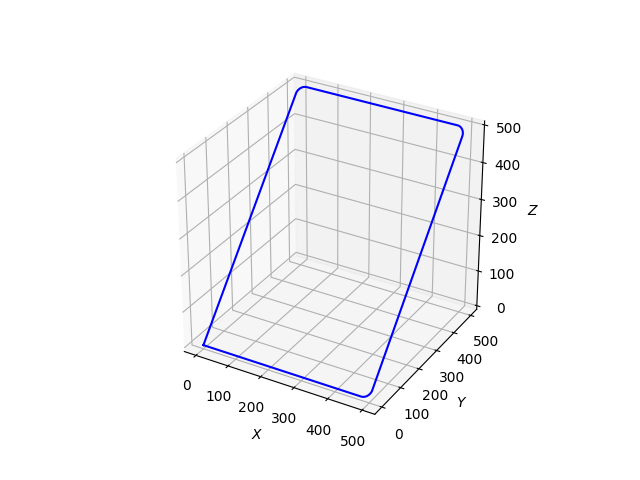

Exact Move Mode

G64: Path Blend Mode

Format:

G64 P<Tolerance>

Description:

Path blend mode. The parser will blend non-colinear moves together with circular arcs to maintain velocity. This results in smoother tool motion at the expense of some precision on the path.

Arguments:

Tolerance (float): Optional. Maximum distance in length units (see G20 and G21*)* output path can deviate from each programmed point. The velocity will be reduced if needed to maintain the path.

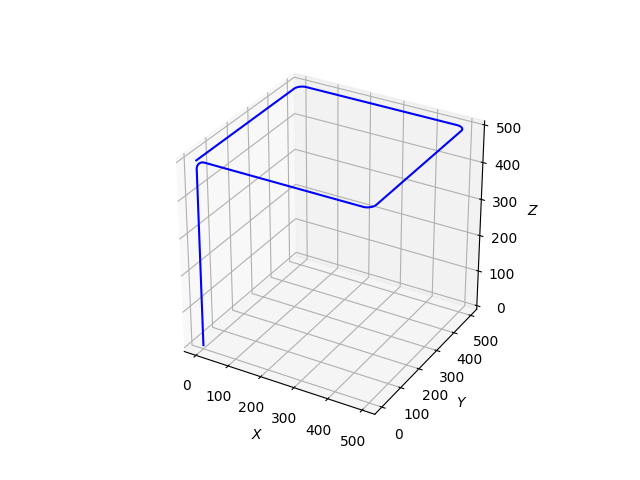

Example:

G91 G21 G64 P10.0

G0 X500

Y500

X-500

Y-500

Path Blend Mode

G90: Absolute Distance Mode

Format:

G90

Description:

Axis numbers (X, Y, Z) usually represent positions in terms of the currently active coordinate system (See G0, G1 and G92).

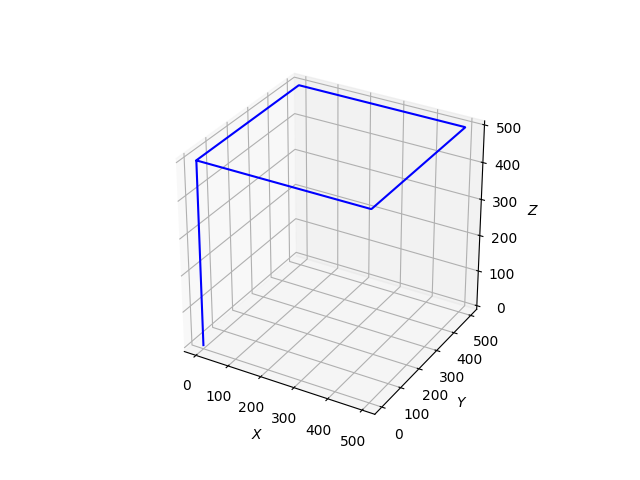

Example:

G21 G90 G64 P1

G0 Z500

X500

Y500

X-500

Y-500

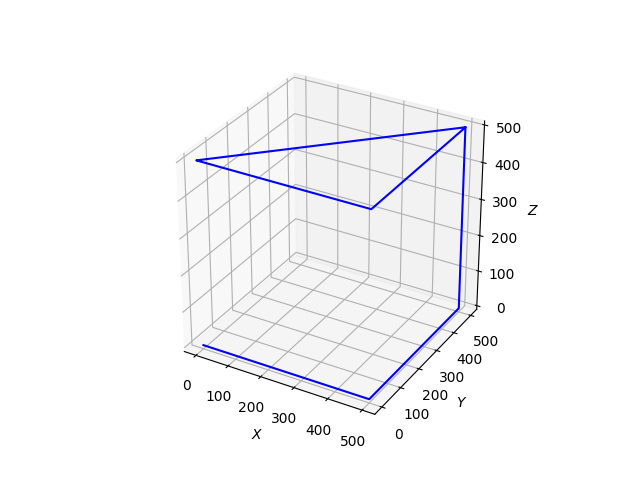

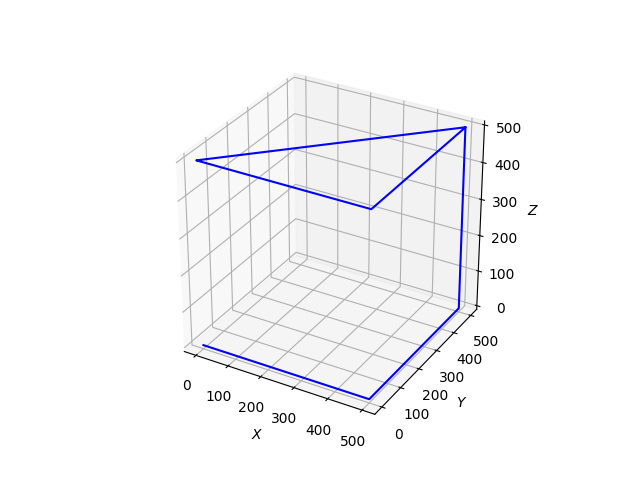

Absolute Distance Mode

G91: Incremental Distance Mode

Format:

G91

Description:

In incremental distance mode, axis numbers usually represent increments from the current coordinate. (See G0, G1 and G92).

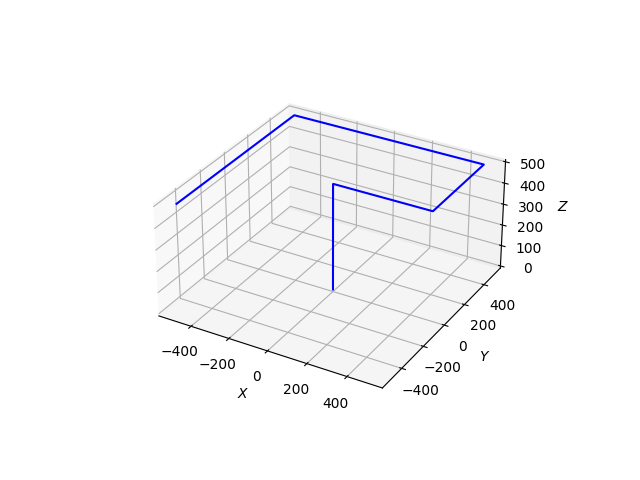

Example:

G21 G91 G64 P1

G0 Z500

X500

Y500

X-500

Y-500

Incremental Distance Mode

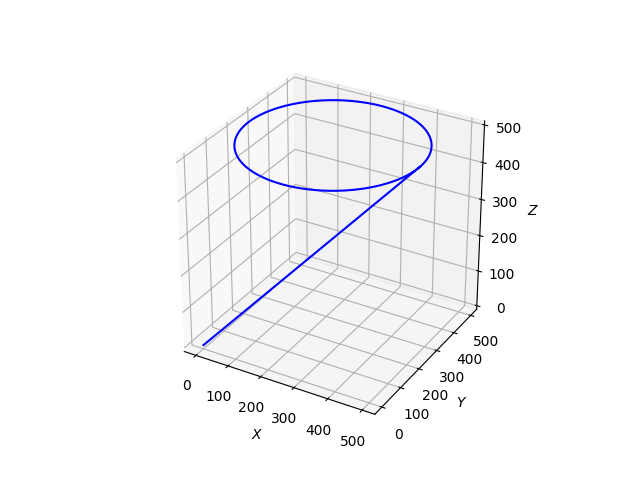

G90.1: Absolute Arc Offset Mode

Format:

G90.1

Description:

Absolute distance mode for I, J & K offsets. When G90.1 is in effect I and J both must be specified with G2/3 for the XY plane or J and K for the XZ plane. (See G2 , G3, G17, G18 and G19).

Example:

G90 G21 G61 G17 G90.1

G0 X500 Y250 Z500

G3 X0 Y250 I250 J250

G3 X500 Y250 I250 J250

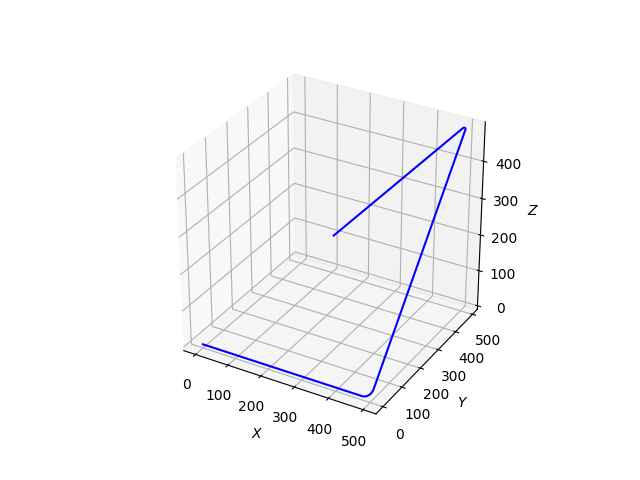

Absolute Arc Offset Mode

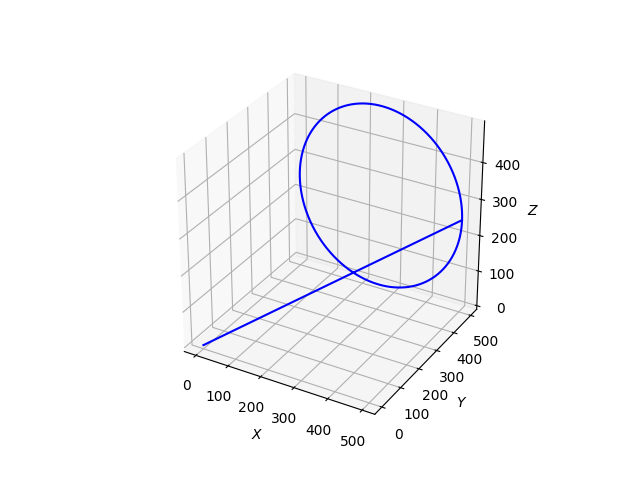

G91.1: Incremental Arc Offset Mode

Format:

G91.1

Description:

Incremental distance mode for I, J & K offsets. Is the default behaviour of the g-code parser. (See G2, G3, G17 and G18).

Example:

G90 G21 G61 G17 G91.1

G0 X500 Y250 Z500

G3 X0 Y250 I-250 J0

G3 X500 Y250 I250 J0

Incremental Arc Offset Mode

G17: Select XY Plane

Format:

G17

Description:

Set the current plane to the XY plane. Affects G2 and G3 commands.

Example:

G90 G21 G61 G17 G90.1

G0 X500 Y250 Z500

G3 X0 Y250 I250 J250

G3 X500 Y250 I250 J250

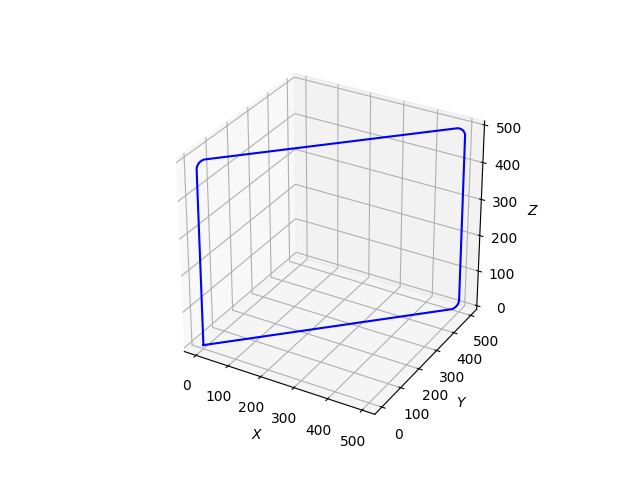

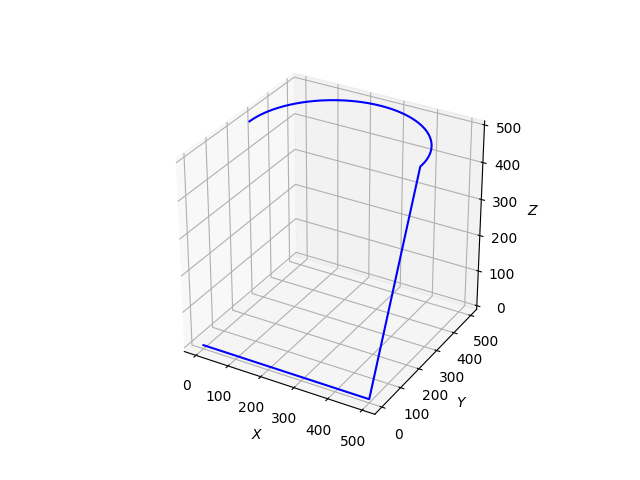

G17

G18: Select ZX Plane

Format:

G18

Description:

Set the current plane to the ZX plane. Affects G2 and G3 commands.

Example:

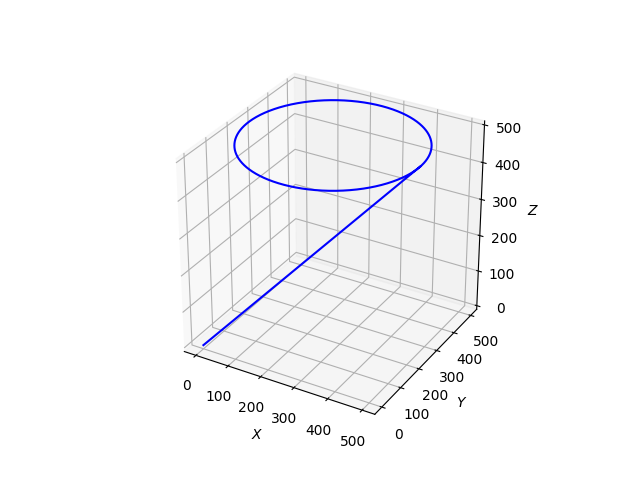

G90 G21 G61 G18 G90.1

G0 X500 Y500 Z250

G3 X0 Z250 I250 K250

G3 X500 Z250 I250 K250

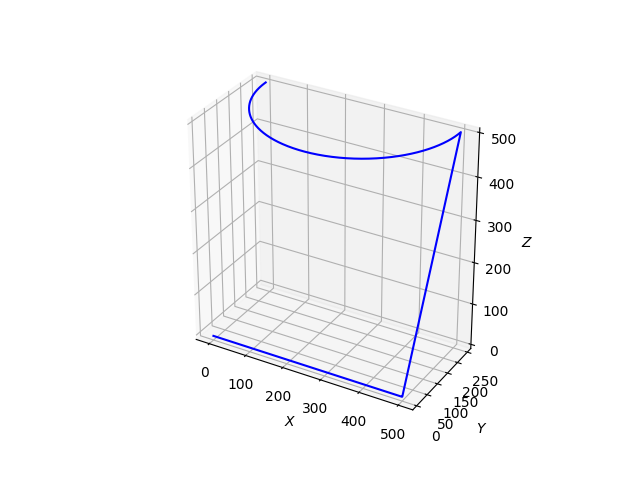

Select ZX Plane

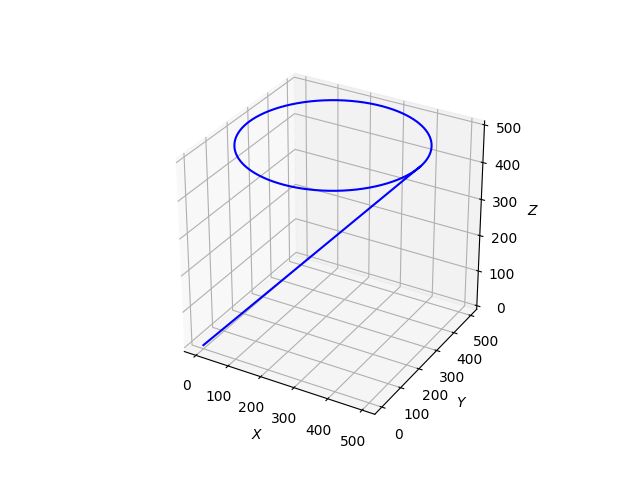

G19: Select YZ Plane

Format:

G19

Description:

Set the current plane to the YZ plane. Affects G2 and G3 commands.

Example:

G90 G21 G61 G19 G90.1

G0 X250 Y500 Z500

G3 Y0 Z250 J250 K250

G3 Y500 Z250 J250 K250

Select YZ Plane

T: Select Tool

Format:

T<x>

Description:

Prepares to change to tool x. The tool is not changed until an M6 is programmed (see M6). The T word may appear on the same line as the M6 or on a previous line. It is OK if T words appear on two or more lines with no tool change.

Arguments:

x (integer): The tool number to be selected. Must be defined in the tool table (see: python example)

Example:

T1 M6 ; selects tool 1 and changes tool

M3 ; starts selected tool in the clockwise direction

M6: Change Tool

Format:

M6

Description:

When called, M3, M4and M5 commands will be affected by the tool previously selected by the latest T command.

Example:

T1 M6 ; selects tool 1 and changes tool

M3 ; starts selected tool in the clockwise direction

G28.1: Set Predefined Position

Format:

G28.1

Description:

When called, the predefined position referred to in G28 is set to the current absolute position

Example:

G90 G21 G61

G0 X500

Y500

Z500

G28.1

G0 Y0

X0

G28

Set Predefined Position

G92: Coordinate System Offset

Format:

G92 <axis><offset> <axis><offset> ...

Description:

G92 makes the current point have the coordinates you want, where the axis words contain the axes you want. All axis words are optional, except that at least one must be used. If an axis word is not used for a given axis, the offset for that axis will be zero.

For example, consider the command G92 X7. If the current point is at X=4 and there is no G92 offset active, the current point will become X=7 and the origin will move -3 in X.

Arguments:

axis (X|Y|Z): At least one axis must be specified

offset (float): Current position of the axis to set.

Example:

G90 G21 G64 P10.0

G0 X500

Y500 Z500

G92 X0 Y0 Z0

G0 X-250 Y-250 Z-250

Coordinate System Offset

G94: Units per Minute Mode

Format:

G94

Description:

Sets the feedrate mode to units per minute. Currently the only feedrate mode option

Example:

G91 G21 G61 G94

G0 X500 F1000 ; Feedrate of 1000 mm/minute

Movement and Tool Commands

Movement and tool commands are used to cause motion of axes and tools. Their behaviour is affected by preceding operational commands.

G0/G00: Rapid Move

Format:

G0 <axis><position> <axis><position> ... F<feedrate>

Description:

Command linear motion of desired axes, where all the axis words are optional. The G0 is optional if the current motion mode is G0. This will produce coordinated motion to the destination point at the maximum rapid rate. G0 is typically used as a positioning move.

Arguments:

axis (X|Y|Z): Optional. Axis to move

position (float): Optional. Incremental G91 or absolute G90 position of resulting move.

feedrate (float): Optional. Desired linear speed of move in length units (see: G21, G20). Ensuing moves will move at this desired feedrate.

Example:

G90 G21 G64 P10.0

G0 X500 Y500 F1000

Z500

X0 Y0

Z0 F500

Rapid Move

G1/G01: Linear Move

Format:

G1 <axis><position> <axis><position> ... F<feedrate>

Description:

Command linear motion of desired axes, where all the axis words are optional. The G1 is optional if the current motion mode is G1. This will produce coordinated motion to the destination point at the desired feed rate. G1 is typically used as a cutting move.

Arguments:

axis (X|Y|Z): Optional. Axis to move

position (float): Optional. Incremental (G91 or absolute G90) position of resulting move.

feedrate (float): Optional. Desired linear speed of move in length units (see: G21, G20). Ensuing moves will move at this desired feedrate.

Example:

G90 G21 G64 P10.0

G1 Y500 Z500 F1000

X500

Y0 Z0

X0 F500

Linear Move

G2: Clockwise Arc Move

Format:

G2 X<offset> Y<offset> Z<offset> i<center_x> j<center_y> k<center_z> F<feedrate>

Description:

Performs clockwise a 2D arc in the selected plane (see: G17, G18, G19). Arc starts at the current position and ends at the defined offsets (absolute if G90 is active, incremental if G91 is active). Size of the circular arc is defined by the arc center coordinates (absolute if G90.1 is active, incremental if G91.1 is active). Full circles must be defined by at least 2 G2 commands.

Arguments:

offset (float): End position of arc in length units (see G21, G20). Only axes in selected plane are necessary (e.g. XY, YZ, ZX).

center_ (float):="" center="" point="" coordinates="" of="" the="" desired="" arc.="" axes="" in="" selected="" plane="" are="" necessary="" (e.g.="" xy,="" yz,="">>

feedrate (float): Optional. Defines feedrate of ensuing moves in length units per second.

Example:

G61 G21 G17 ; select XY plane for arcs

G90 ; offsets are in absolute position mode

G90.1 ; center_ in absolute position mode

G0 X500

G0 Y250 Z500

G2 X0 Y250 I250 J250

Clockwise Arc Move

G3: Counterclockwise Arc Move

Format:

G3 X<offset> Y<offset> Z<offset> i<center_x> j<center_y> k<center_z> F<feedrate>

Description:

Performs a counterclockwise 2D arc in the selected plane (see: G17, G18, G19). Arc starts at the current position and ends at the defined offsets (absolute if G90 is active, incremental if G91 is active). Size of the circular arc is defined by the arc center coordinates (absolute if G90.1 is active, incremental if G91.1 is active). Full circles must be defined by at least 2 G2 commands.

Arguments:

offset (float): End position of arc in length units (see G21, G20). Only axes in selected plane are necessary (e.g. XY, YZ, ZX).

center_ (float):="" center="" point="" coordinates="" of="" the="" desired="" arc.="" axes="" in="" selected="" plane="" are="" necessary="" (e.g.="" xy,="" yz,="">>

feedrate (float): Optional. Defines feedrate of ensuing moves in length units per second.

Example:

G61 G21 G17 ; select XY plane for arcs

G90 ; offsets are in absolute position mode

G90.1 ; center_ in absolute position mode

G0 X500

G0 Y250 Z500

G3 X0 Y250 I250 J250

Counterclockwise Arc Move

G4: Dwell

Format:

G4 P<seconds>

Description:

Causes the machine to stay in place for a period of time.

Arguments:

seconds (float): Time in seconds the machine will stay stationary

{:/accordion}

{::accordion title=’G28: Move To Predefined Position’ code=’’}

Format:

G28

Description:

Causes the machine to return to its predefined position, as set in G28.1. If no position is previously set, machine will return to the origin.

Example:

G90 G21 G61

G0 X500

Y500

Z500

G28.1

G0 Y0

X0

G28

Go To Predefined Position

M3: Start Tool Clockwise

Format:

Implicit method:

M3 $<tool number>

Explicit method:

M3 A<device ID> P<port>

Description:

Used for interfacing with end of arm tools that are linked to digital outputs. When called, the selected tool (and as a result, the associated digital output) will be activated to cause a clockwise rotation of the tool. Tools can be controlled implicitly or explicitly. The implicit method of tool control relies on external definition of the tool via python API.

Arguments:

Implicit Method:

tool number (int): Optional. If used, controls the given tool number. The associated clockwise output will be pulled active, while the counterclockwise output will be pulled inactive. If not used, M3 will control the last activated tool (see: T, M6).

Explicit Method:

device ID (int): Directly selects the desired digital output’s device ID.

port (int): Directly sets the desired port value to HIGH (24V).

Example:

Implicit Method:

Python Snippet:

from MachineMotion import *

clockwise = DIGITAL_OUTPUT_STATE(deviceId=1,port=0,value=1)

counterclockwise = DIGITAL_OUTPUT_STATE(deviceId=1,port=1,value=1)

tool1 = TOOL(1,clockwise,counterclockwise)

m = MachineMotionV2()

m.configPathMode({"X": 1, "Y": 2},tool1)

G-Code Snippet:

G90 G21

T1 M6 ; selects tool one and activates it

G0 X100 Y100

M3 ; starts activated tool clockwise

G1 X200 Y200

M5 ; stops activated tool

Explicit Method:

G90 G21

G0 X100 Y100

M3 A1 P0 ; Pulls device ID 1 port 0 HIGH

G1 X200 Y200

M5 A1 P0 ; Pulls device ID 1 port 0 LOW

M4: Start Tool Counterclockwise

Format:

Implicit method:

M3 $<tool number>

Explicit method:

M3 A<device ID> P<port>

Description:

Used for interfacing with end of arm tools that are linked to digital outputs. When called, the selected tool (and as a result, the associated digital output) will be activated to cause a counterclockwise rotation of the tool. Tools can be controlled in two ways: implicitly with the “$” operator method and directly with the “A”,”P” method. The implicit method relies on external definition of the tool via python API.

Arguments:

Implicit Method:

tool number (int): Optional. If used, controls the given tool number. The associated counterclockwise output will be pulled active, while the counterclockwise output will be pulled inactive. If not used, M4 will control the last activated tool (see: T, M6).

Explicit Method:device ID (int): Directly selects the desired digital output’s device ID.

port (int): Directly sets the desired port value to HIGH (24V).

Example:

Implicit Method:

Python Snippet:

from MachineMotion import *

clockwise = DIGITAL_OUTPUT_STATE(deviceId=1,port=0,value=1)

counterclockwise = DIGITAL_OUTPUT_STATE(deviceId=1,port=1,value=1)

tool1 = TOOL(1,clockwise,counterclockwise)

m = MachineMotionV2()

m.configPathMode({"X": 1, "Y": 2},tool1)

G-Code Snippet:

G90 G21

T1 M6 ; selects tool one and activates it

G0 X100 Y100

M4 ; starts activated tool counterclockwise

G1 X200 Y200

M5 ; stops activated tool

Explicit Method:

G90 G21

G0 X100 Y100

M4 A1 P1 ; Pulls device ID 1 port 1 HIGH

G1 X200 Y200

M5 A1 P1 ; Pulls device ID 1 port 1 LOW

M5: Stop Tool

Format:

Implicit method:

M3 $<tool number>

Explicit method:

M3 A<device ID> P<port>

Description:

Used for interfacing with end of arm tools that are linked to digital outputs. When called, the selected tool (and as a result, the associated digital output) will be activated to cause a clockwise rotation of the tool. Tools can be controlled in two ways: implicitly with the “$” operator method and directly with the “A”,”P” method. The implicit method relies on external definition of the tool via python API.

Arguments:

Implicit Method:

tool number (int): Optional. If used, controls the given tool number. The associated clockwise and counterclockwise outputs will be pulled inactive. If not used, M5 will control the last activated tool (see: T, M6)

Explicit Method:

device ID (int): Directly selects the desired digital output’s device ID.

port (int): Directly sets the desired port value to LOW (0V).

Example:

Implicit Method:

Python Snippet:

from MachineMotion import *

clockwise = DIGITAL_OUTPUT_STATE(deviceId=1,port=0,value=1)

counterclockwise = DIGITAL_OUTPUT_STATE(deviceId=1,port=1,value=1)

tool1 = TOOL(1,clockwise,counterclockwise)

m = MachineMotionV2()

m.configPathMode({"X": 1, "Y": 2},tool1)

G-Code Snippet:

G90 G21

T1 M6 ; selects tool one and activates it

G0 X100 Y100

M3 ; starts activated tool clockwise

G1 X200 Y200

M5 ; stops activated tool

Explicit Method:

G90 G21

G0 X100 Y100

M3 A1 P0 ; Pulls device ID 1 port 0 HIGH

G1 X200 Y200

M5 A1 P0 ; Pulls device ID 1 port 0 LOW

Python Example

import sys

sys.path.append("../..")

from MachineMotion import *

mm = MachineMotionV2()

### This example demonstrates the creation and execution of a simple 2D path ###

# Expected configuration for this example (via Control Center)

# Axis 1

# Drive Number(s): 1, 2

# Axis Type: Enclosed Timing Belt with 5:1 gearbox

# Motor Size: Large

# Axis 2

# Drive Number(s): 3

# Axis Type: Enclosed Ballscrew

# Motor Size: Large

GCODE_STRING = """

(Operational mode commands)

G90 ; Absolute position mode

G90.1 ; Absolute arc centre

G21 ; Use millimeter units

G17 ; XY plane arcs

G64 P0.5 ; Blend move mode, 0.5 mm tolerance

(Movement and output commands)

G0 X60 Y110 F1000 ; Travel move at 1000 mm/minute

M3 $1 ; Start tool 1 in clockwise direction

G1 X110 Y110

G2 X110 Y10 I100 J60 ; Clockwise arc

G1 X60 Y10

G2 X60 Y110 I60 J60

G4 P1.0 ; Dwell for 1 second

M5 $1 ; Stop tool 1

G0 X1 Y1

"""

# Optional: If your path contains M3-4-5 commands,

# define device,port and on value of both tool directions.

# clockwise must be defined for M3 commands

clockwise = DIGITAL_OUTPUT_STATE(deviceId=1, port=0, value=1)

counterClockwise = DIGITAL_OUTPUT_STATE(1, 1, 1)

tool1 = TOOL(1, clockwise, counterClockwise)

# associate with the parent drive

driveAssociation = {"X": 1, "Y": 3}

# Configure the path following mode

mm.configPathMode(driveAssociation, tool1)

maxPathAcceleration = 1000 # mm/s^2

mm.setAxisMaxAcceleration(1,1000)

mm.setAxisMaxAcceleration(3,1000)

mm.setAxisMaxSpeed(1,500)

mm.setAxisMaxSpeed(3,500)

mm.moveToHome(1)

mm.moveToHome(3)

mm.waitForMotionCompletion()

# Start Path Following.

mm.startPath(GCODE_STRING, maxPathAcceleration)

running = True

while running:

pathStatus = mm.getPathStatus()

running = pathStatus['running']

print('--> Got Path Status: ', pathStatus)

time.sleep(0.5)

mm.stopPath()

print("--> Done!")