.png)

General Description

Vention's Rapid Series Sanding solves labor and quality challenges for cabinet manufacturers and other woodworkers. This turnkey solution can easily handle multiple cabinet sizes and designs, with the option to create recipes in minutes through an intuitive touch screen pendant. Optimized for 3M™ Abrasives, the Rapid Series Sanding solution was designed to maximize performance and is supported by 3M abrasive process experts. With rapid shipping and deployment supported by a skilled remote engineering team, the integration is a seamless, zero-stress experience.

Available Configurations

The Rapid Series Sanding is capable of handling various panel sizes by combining its four stations.

.png)

Inclusions and options

Vention’s Rapid Series Sanding comes with the following:

Vention and 3M™ Abrasives collaboration from the start, ensuring the sanding process is optimized for your product.

3M™ Abrasives starter pack kit; containing

3M™ Hookit™ Clean Sanding Sheet, 236U, 3x4 in (50 sheets) in the following grits: 150,180, 220, 320

3M™ Clean Sanding Pads Hook Saver, 3x4 in

3M™ Clean Sanding Interface Disc Pads, 3x4 in

MachineApp Sanding Software

Remote Support Subscription (first year included)

Additionally, it is possible to add the following accessories and software upgrades for an additional cost:

Maintenance kit; containing

3M™ Clean Sanding Pad Hook Saver, 3x4 in (10 units)

3M™ Clean Sanding Interface Disc Pad, 3x4 in (6 units)

Vention Vacuum Pod Foams (32 units)

Keyence Mini-Slim Diffuse Sensor (2 units)

Pneumatic Sensor (2 units)

12mm & 6mm OD Blue Tubing (5 m of each)

Components overview

.png)

General technical specifications

Specification | Value |

|---|---|

Robot type | Fanuc CRX-30iA (repeatability of +/- 0.05 mm) |

EOAT brand and options | PushCorp pneumatic orbital sanding system Rectangular pad (4 x 3 in) & passive compliance |

Machine footprint | 69 (D) x 95 (W) in |

Panel holding mechanism | Movable vacuum pods on rails |

Material supported | Medium density fibreboard (MDF) High density fibreboard (HDF) Hardwood Softwood Wood veneer |

Panel types supported | Simple, shaker, recessed, raised, step shaker |

Panel maximum dimensions | 90 in x 36 in Rails and Stiles: 4 in wide |

Panel minimum dimensions | 6 in x 7.5 in |

Tool air supply | 17 SCFM @ 90PSI |

System air supply | 7.5 SCFM @ 90PSI |

Electrical provisions | 2× 120V outlets on separate 15A breakers (or one 30A breaker) |

Operating temperature range | 10 - 40 °C |

Maximum operating humidity | 85% |

Installation and anchoring

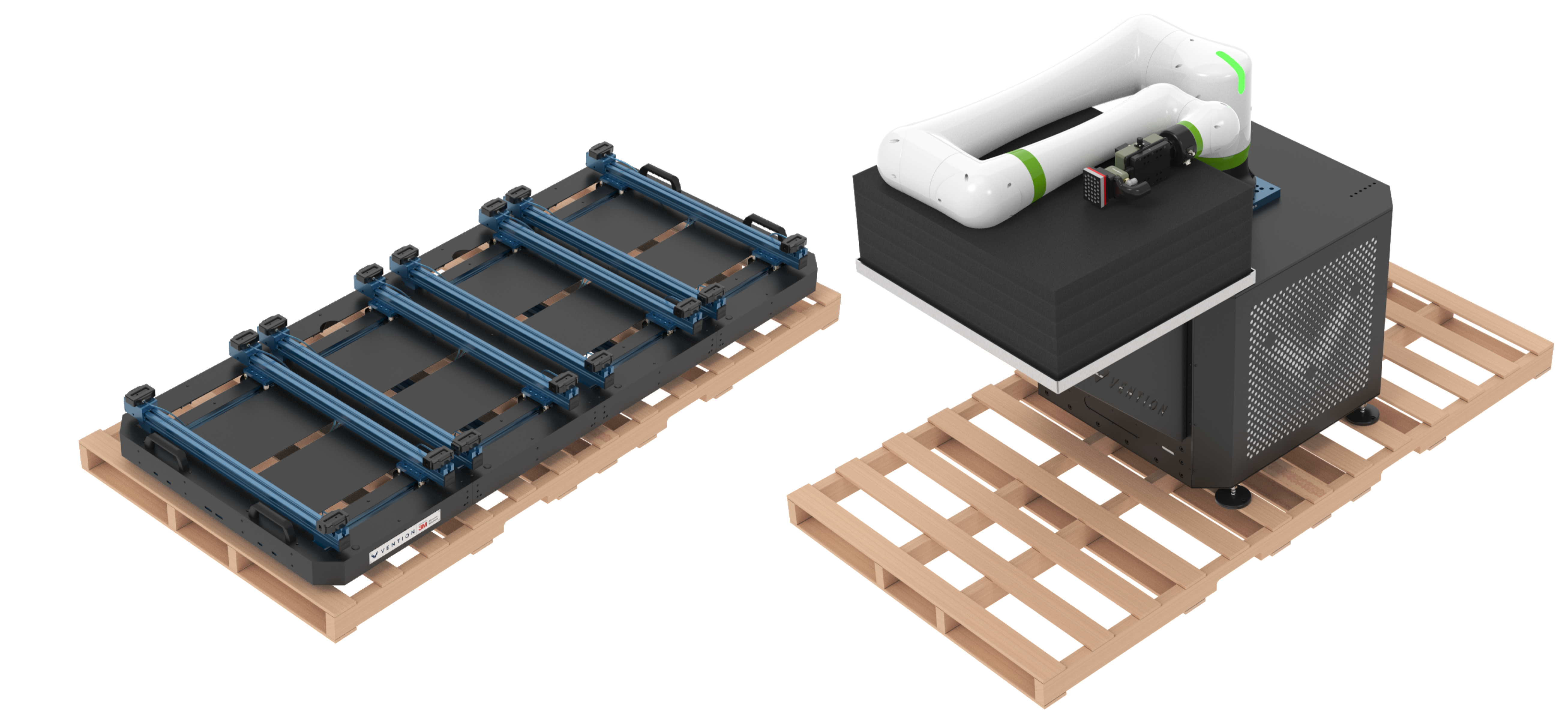

The base can be moved using a forklift (if on a pallet) or a pallet jack (directly underneath the base). In order to move the base directly with a pallet jack, the four anchoring brackets on the front and back must be removed if the pallet jack is wider than 585mm (23in). The table can be lifted with a forklift (using straps on the handles) or by hand with the handles on each side.

.png)

The height and levelling should be adjusted with the levelling feet once the base is in the desired location. Anchor the base securely to the ground using the anchor bracket (if they were removed to move the base, reinstall them on the base).