Overview

The mechanical assembly checklist should be used as a final check once the system is assembled.

Use the following checks to ensure that your system is assembled correctly.

General assembly

1. Extrusions | Extrusions are assembled according to CAD design.

| |

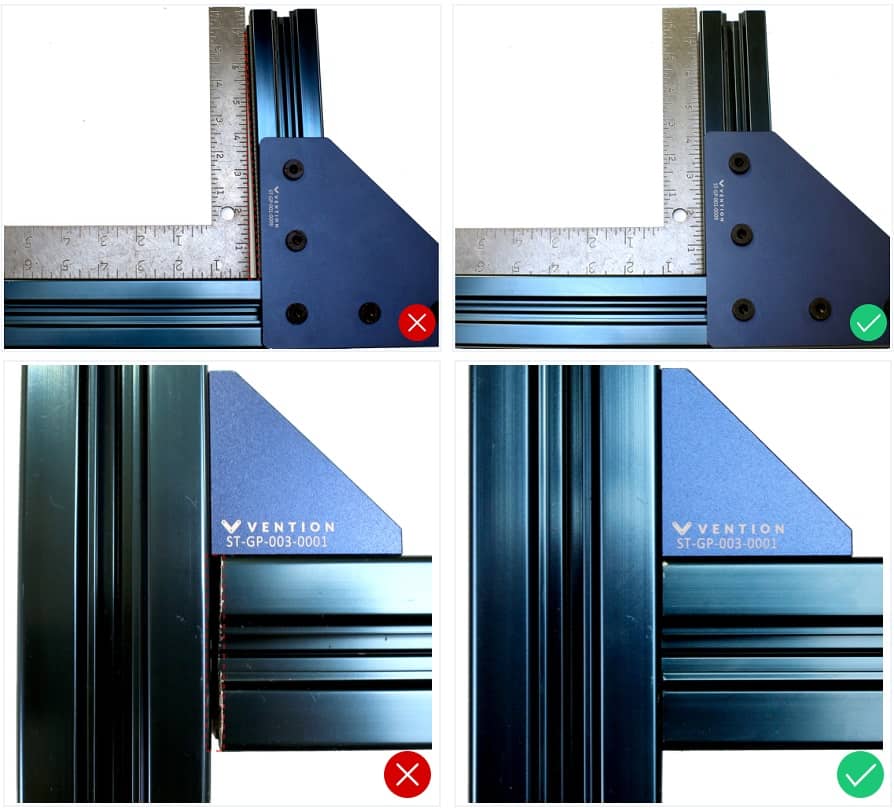

2. Gussets | High-precision (HP) and general-precision (GP) gussets are installed in correct locations. | |

3. Plates | Assembly plates are properly mounted; no fasteners are missing. | |

4. Frame | Base frame can support more than enough weight.

For details, see the assembly guide . |

|

5. Screws | Screws are securely tightened.

For details, see the anti-vibration products guide . | |

6. Level | System is leveled.

| |

7. Cables and tubes | Cables and tubes are sufficiently long and run along clear paths.

For details, see the cable management guide . | |

8. Hinges | Hinges move smoothly. | |

9. Safety interlock | Safety interlocks are adjusted and fully engaged. | |

10. Custom parts | Custom parts are deburred and have no sharp edges. |

Rack and pinion

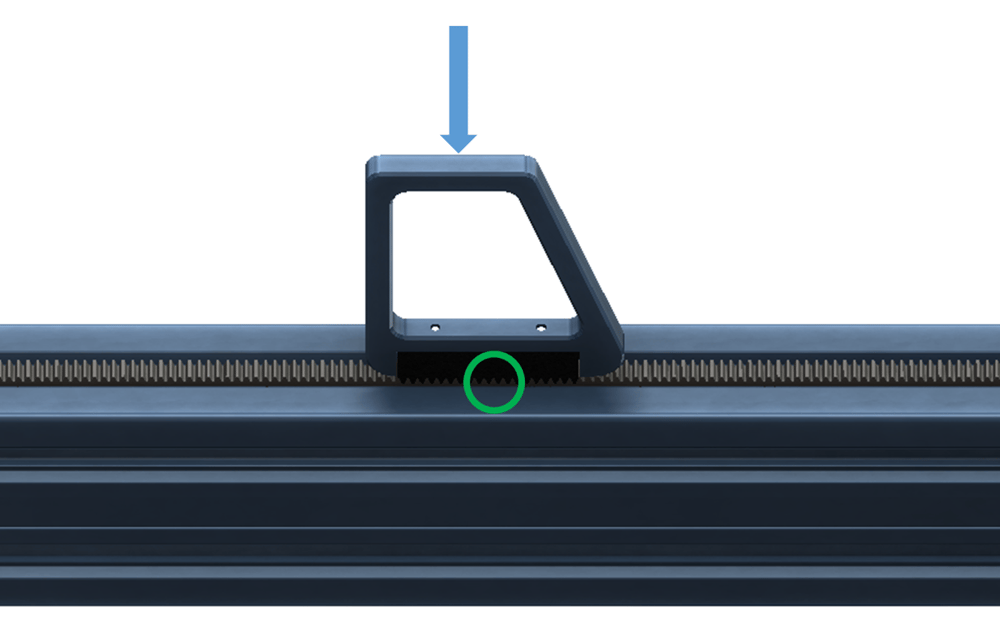

11. Rack spacing | Gear rack sections are properly joined.

For details, see the rack and pinion actuator guide . |

|

12. End-stop brackets | End sensor brackets are tightened on rack. | |

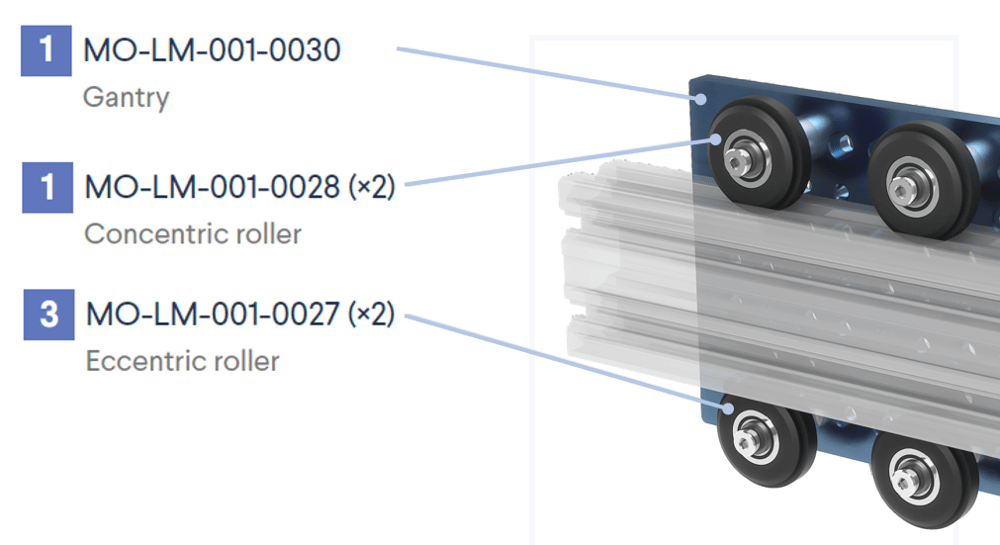

13. Housing | Bearings and/or rollers are securely mounted on housing. |

Alignment

14. Rails |

| |

15. Shaft | If system has butt-jointed rails: Butt-joints have no chamfer, gaps, or misalignment.

| |

16. Roller wheels | Eccentric rollers are all on one side and properly adjusted; concentric rollers are all on the opposite side. |

Lubrication and maintenance

Find step-by-step instructions for these components in the maintenance guide.

17. Linear ball bearings | Installation: Ball bearings lubricated. |

|

18. Plain bearings | Installation (recommended): Shaft cleaned with 3-in-1 oil. |

|

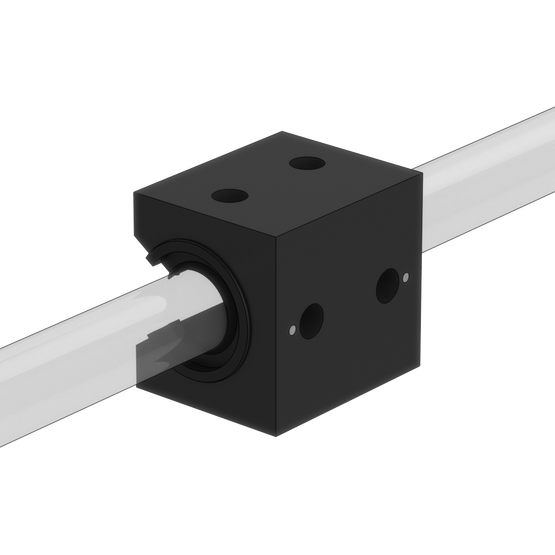

19. Ball screws | Installation: Ball screws lubricated. |

|

20. Rack and pinion | Installation: Gear racks lubricated. |

|

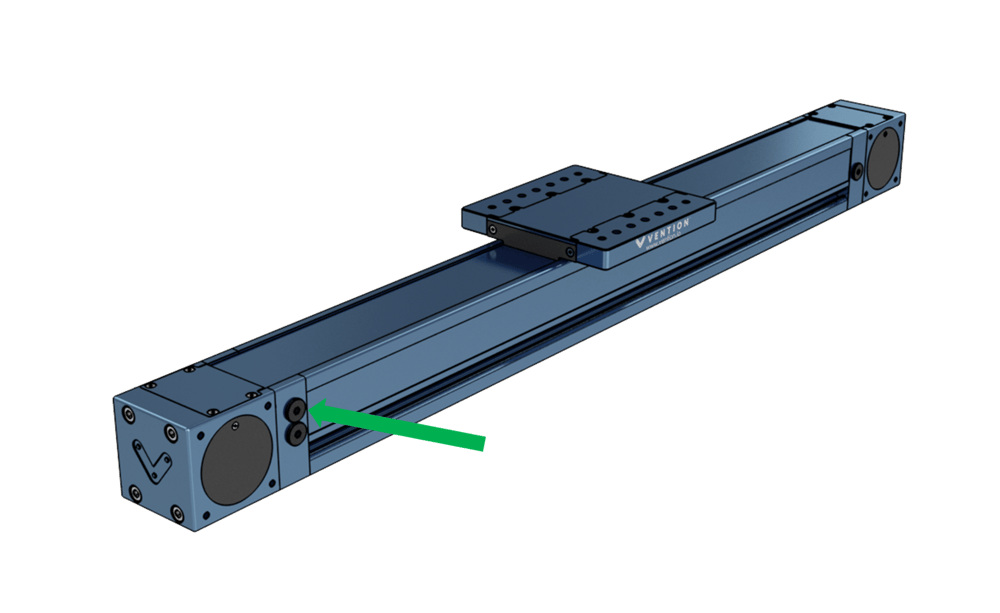

21. Enclosed timing belt actuator | Installation: N/A (ships pre-lubricated). |

|

22. Rotary actuator | Installation: N/A (ships pre-lubricated). |

|

Sensors

23. End-stop sensor | If using an actuator: End-stop sensors are functioning (to detect when gantry reaches end of travel). |

24. End-stop bumper | Sensor has sufficient clearance from plate at end-stop position.

|

25. Sensor mounting | Sensors have enough clearance and are not intercepted by the movement of other components. |

Motors

26. Motor | Before installation: Shaft has key installed on it. |

27. Power transmission devices | Before installation: Design follows proper order of motor, gearbox, and brake. |

.jpg)

.jpg)

.jpg)

.png)

.png)