Overview

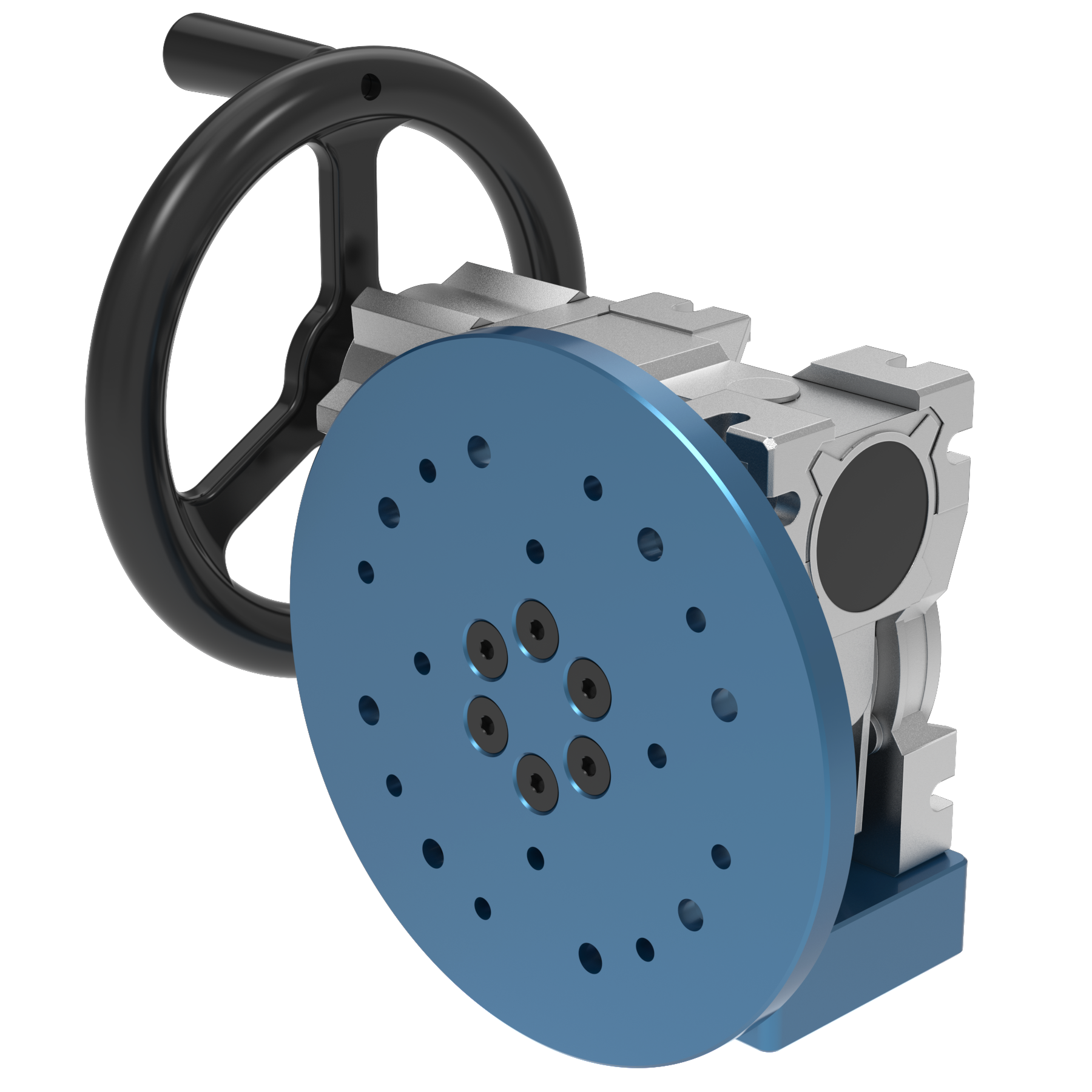

This guide covers the setup and specifications of the Vention gearbox assembly. This assembly includes a 70:1 gearbox and a 200mm handwheel for precise manual control. All parts are designed for seamless interfacing with the Vention ecosystem.

Two kit options will be detailed:

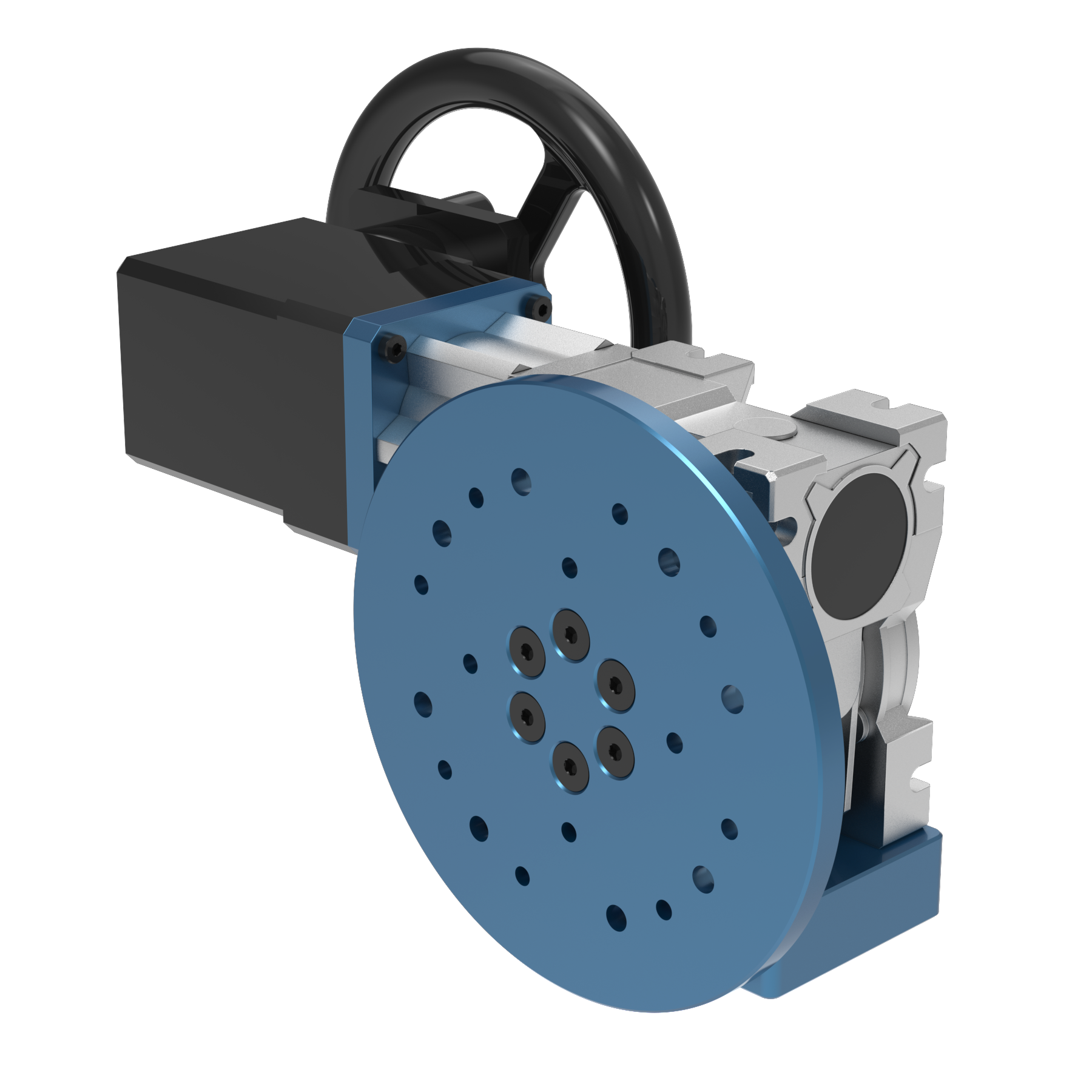

A right angle gearbox attachment to allow for the input axis to be parallel with the output axis (MO-RM-007-1000)

An additional support for the output shaft to allow for increased payload (MO-RM-007-0010)

Assembly & Specifications:

MO-RM-007-0000 Worm Gearbox Kit, 70:1 Ratio:

Kit Contents:

- 1x Worm Gearbox;

- 1x Hand Wheel;

- 1x Flanged Output Shaft Assembly;

- 1x Gearbox Attachment Block;

- 4x M8×18 screws;

- 1x M6×16mm screw;

- 6x M8×65mm screws.

Installation Instructions

Mount the plate: Bolt the base plate to the extrusion structure.

.png)

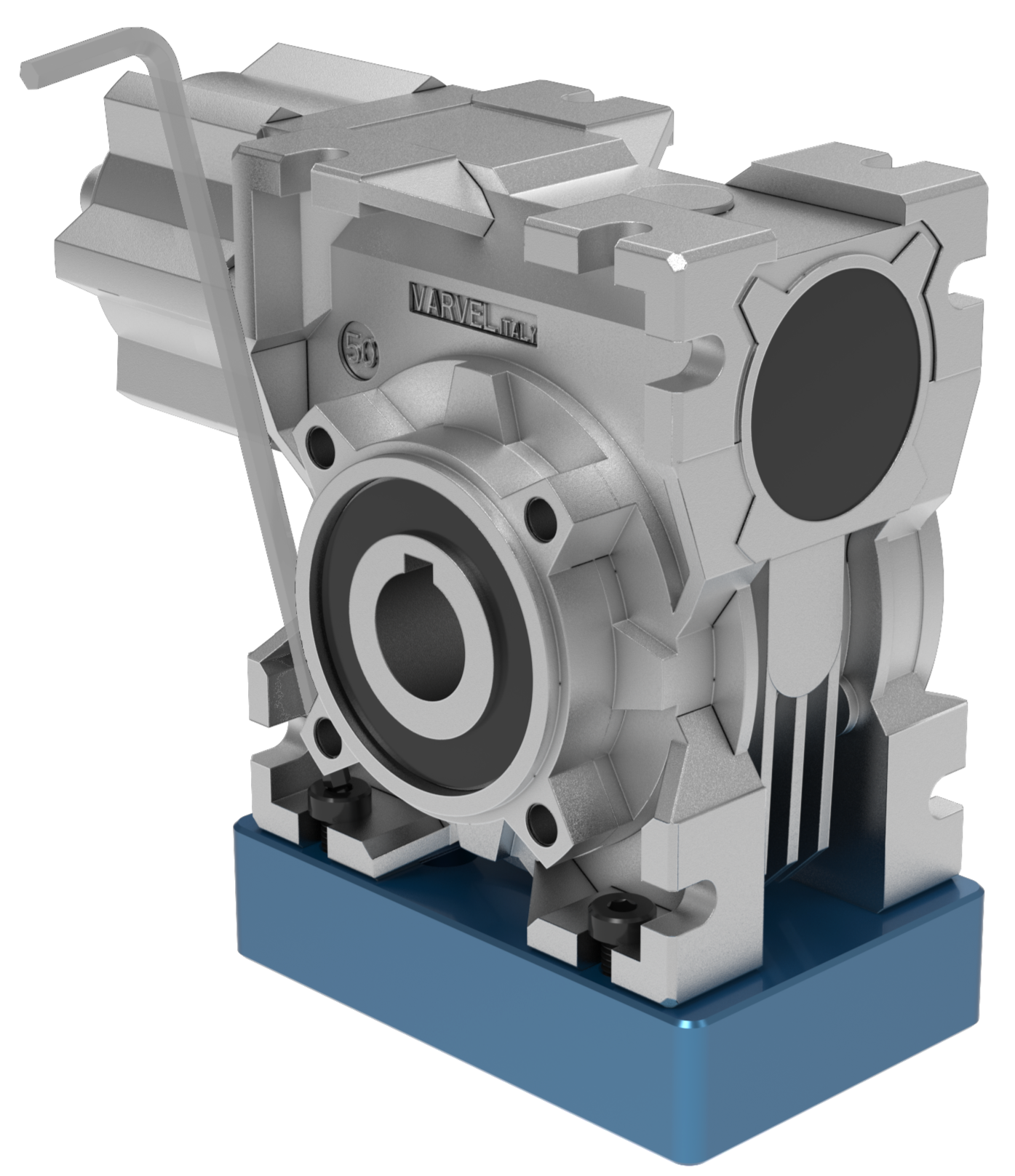

Secure the gearbox: Fasten the gearbox to the mounting plate using either a ball-end Allen key, a ball-end t-handle or a stubby hex key to easily reach the bolts.

.png)

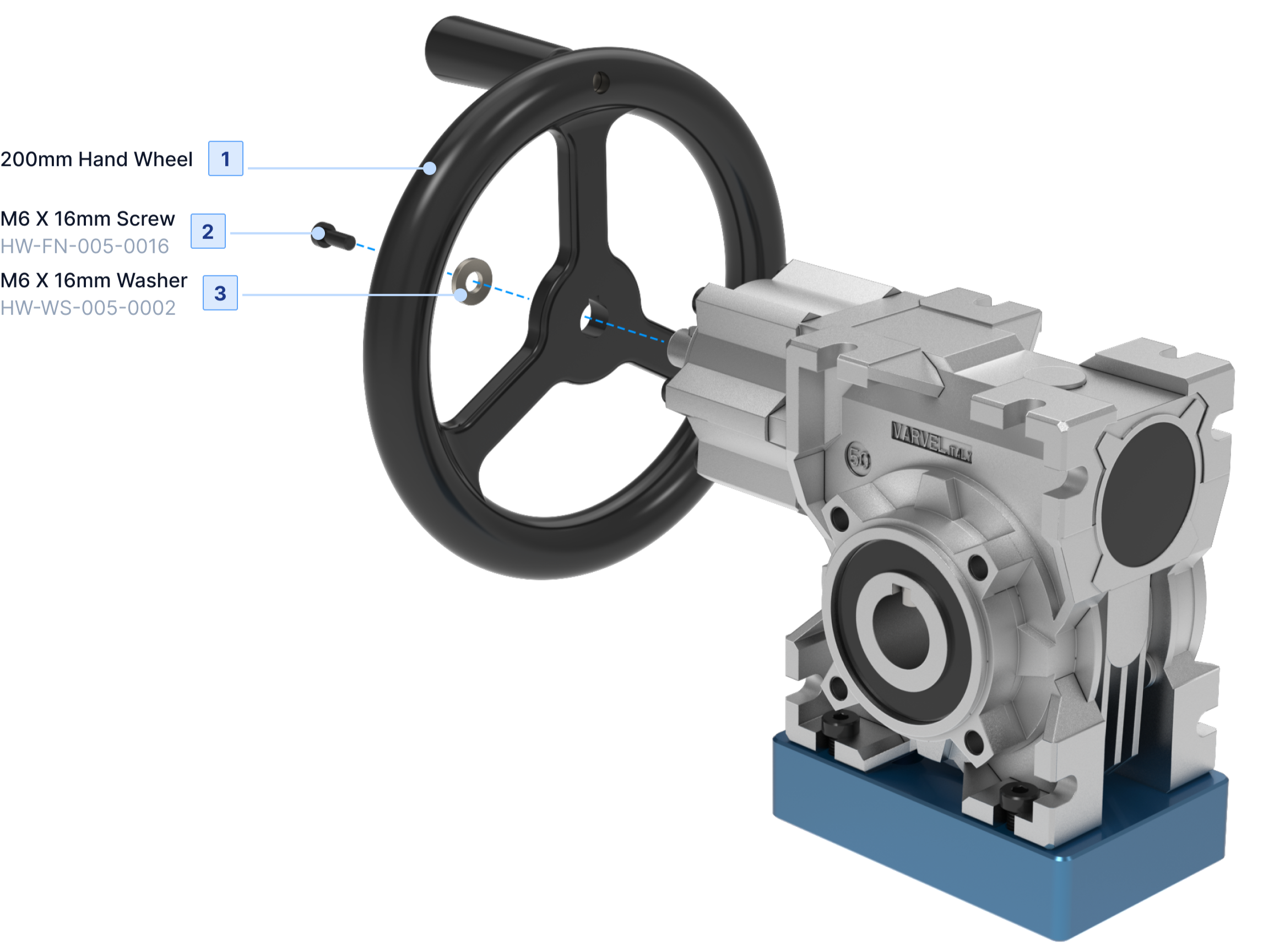

Install the hand wheel: Slide the hand wheel onto the input shaft of the gearbox. Fasten it using the provided washer and M6 × 16mm screw to prevent the hand wheel from sliding off.

Line up the keys: The end of the shaft has small raised rectangular parts called keys. They must be lined up with the matching grooves, or keyways, inside the gearbox opening.

Slide it In: Once those keys and grooves are aligned, push the shaft into the gearbox. The shaft can be slid in from either side of the gearbox, both orientations are supported.

.png)

Seat It firmly: Continue pushing the shaft until the stepped section is fully seated.

Lock It down: Slide the provided shaft collar onto the exposed end of the shaft. The collar can then be secured by tightening the two fasteners to a torque between 9 and 11 Nm. This will ensure that the shaft cannot slide out of the gearbox assembly.

Discard plate: Once you are done, you will be left with one extra plate with the part number MO-RM-007-0002, this is normal and the plate is to be discarded.

Technical Specifications

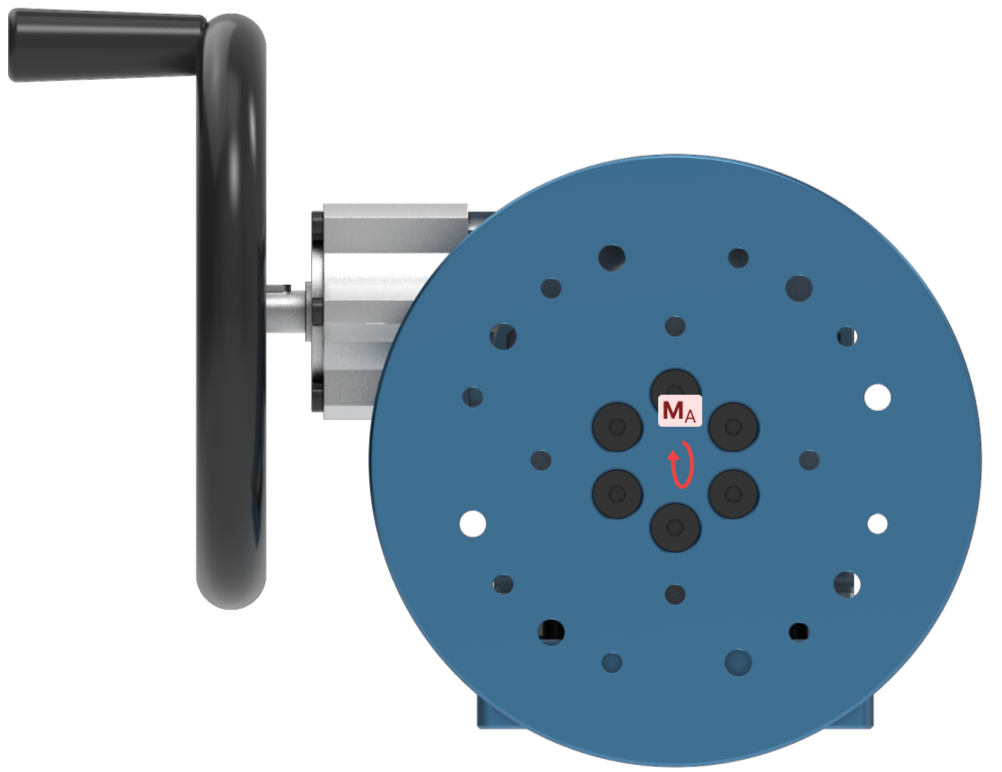

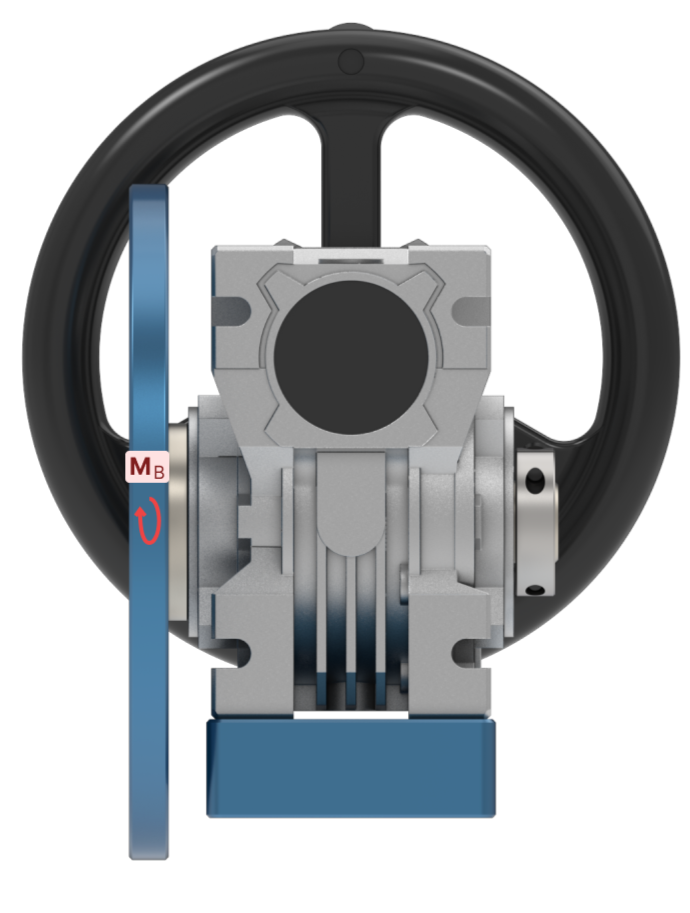

Ratio | 70:1 |

Maximum Output Torque* [Nm] (MA) | 58 |

Output Radial Load [N] | 4200 |

Output Axial Load [N] | 840 |

Maximum Payload with MO-RM-007-0010 [kg] | 453 |

Maximum Payload without MO-RM-007-0010 [Nm] (MB) | 400 |

*Exceeding this output torque will reduce the life of the gears. Please consult our Application Engineering department for any additional information.

|

|

MO-RM-007-1000 Right Angle Input Kit for Worm Gearbox:

Kit Contents:

- 1x Worm Gearbox;

- 1x Hand Wheel;

- 1x Flanged Output Shaft Assembly;

- 1x Gearbox Attachment Block;

- 4x M8×18 screws;

- 1x M6×16mm screw;

- 6x M8×65mm screws;

- 1x M5×16mm screw;

- 1x Right Angle Gearbox, 1:1.

Kit Contents:

Installation Instructions

To begin, follow the installation instructions listed under MO-RM-007-0000 Worm Gearbox Kit, 70:1 Ratio in the section above but skip the step instructing to install the hand wheel on.

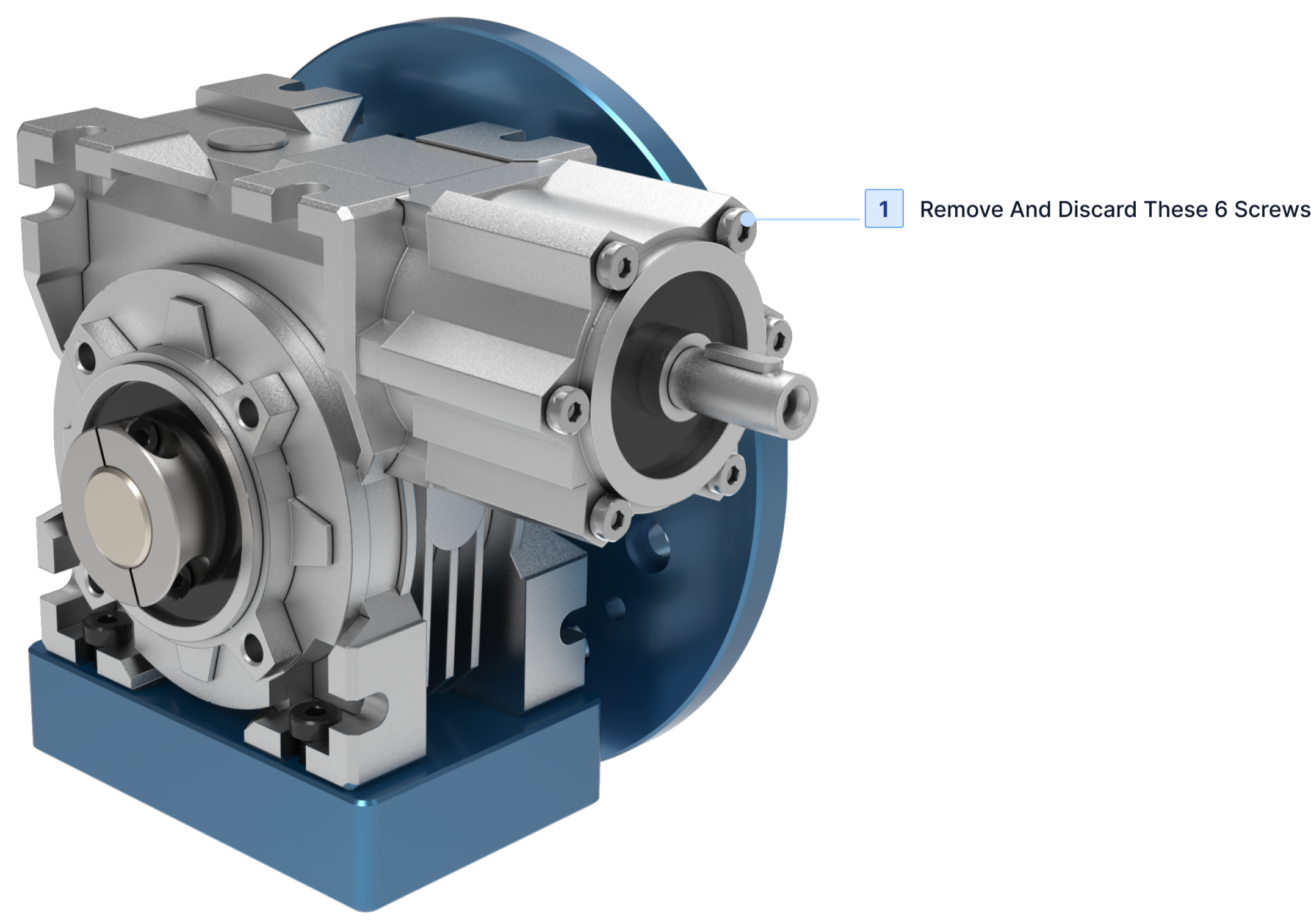

Remove hardware: Locate the input shaft on the main gearbox. Remove and discard the 6 M6 screws located around the input shaft of the worm gearbox.

Install the adaptor plate: Take the right angle adaptor plate and align the mounting holes with the matching set on the gearbox. Use the six M6 × 60mm screws provided in the kit to securely bolt the adaptor plate into position. Torque these screws in a star pattern to a torque between 9 and 11 Nm.

.png)

Slide the right-angle gearbox on: Carefully slide the right angle gearbox onto the exposed shaft of the gearbox kit. Use the four M6 × 20mm fasteners provided to secure the right angle gearbox to firmly to the adaptor plate.

.png)

Install the hand wheel: Slide the hand wheel onto the shaft of the 1:1 right angle gearbox. Fasten it using the provided washer and M5 × 16mm screw to prevent the hand wheel from sliding off.

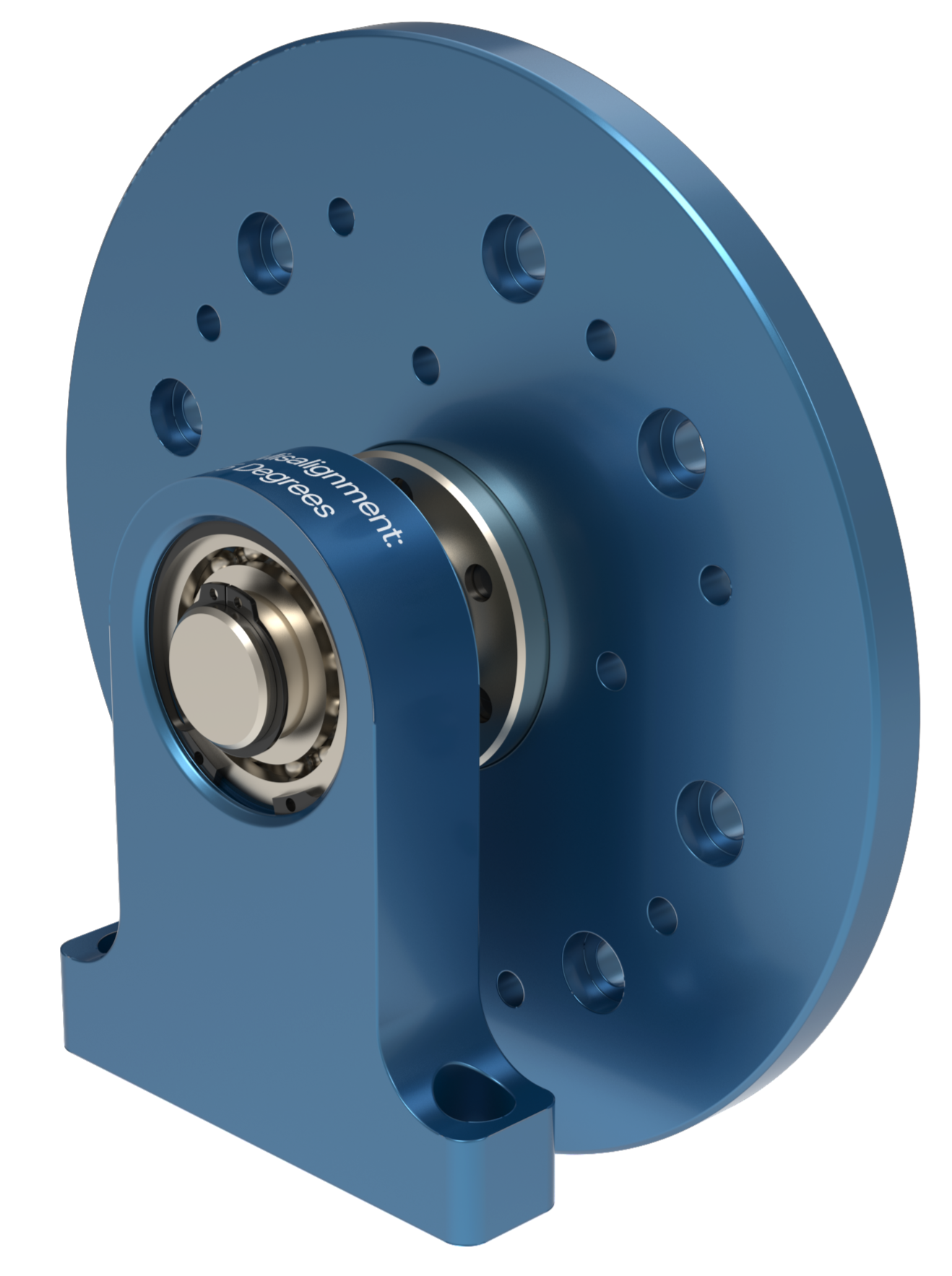

MO-RM-007-0010 Self Aligning Rotary Jig Support:

This self-aligning support can be used to compensate for small shaft misalignment errors of less than 2.5 degrees during installation. The support can be mounted to the Vention extrusion and accommodates the mounting pattern as the flange output shaft assembly.

If the shaft is too far off-axis (over 2.5 degrees), the bearing seals may pop out. If this happens, they can be easily pressed back into the bearing by hand.

Technical Specifications

Maximum Misalignment [degrees] | 2.5 |

Maximum Payload [kg] | 225 |

Maximum Rotation Speed [RPM] | 18000 |

Maximum Dynamic Radial Load [kN] | 14.3 |

Maximum Static Radial Load [kN] | 4.0 |

Worm Gearbox (MO-RM-007-0000) Maximum Payload with this support [kg] | 453 |