Overview

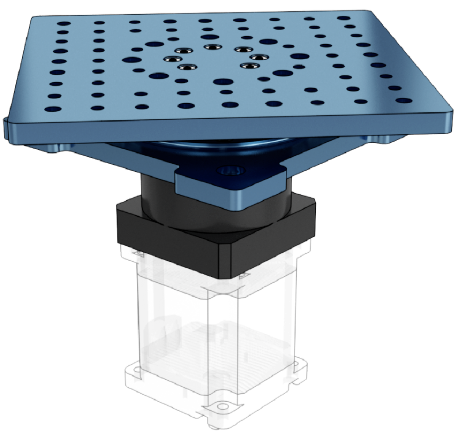

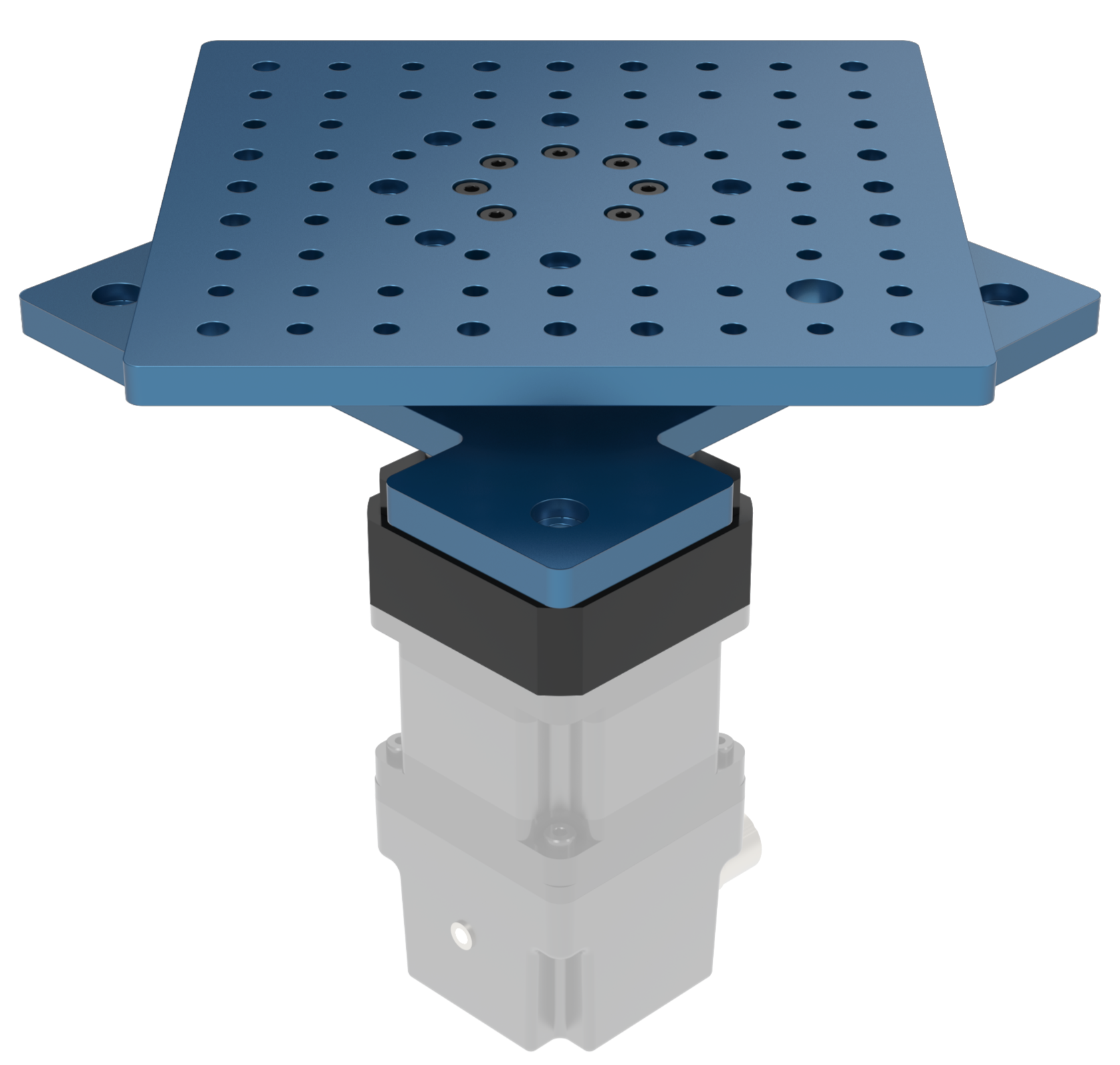

The assembly of the Rotary Actuator v2 and Heavy Duty Rotary Actuator consists of a concealed 10:1 and 20:1 respectively flanged gearbox between two Vention compatible plates. The bottom mounting allows for any combination of Vention’s NEMA 34 stepper servo motors. With a 10:1 and 20:1 reduction present on the actuators, multiple levels of torque can be achieved. The bottom plate also features mounting holes that interface perfectly with Vention extrusions. The top plate features multiple counterbored and threaded holes for all your mounting purposes.

This document covers requirements for current version of MachineMotion controller. For previous version, refer to link below:

Applications

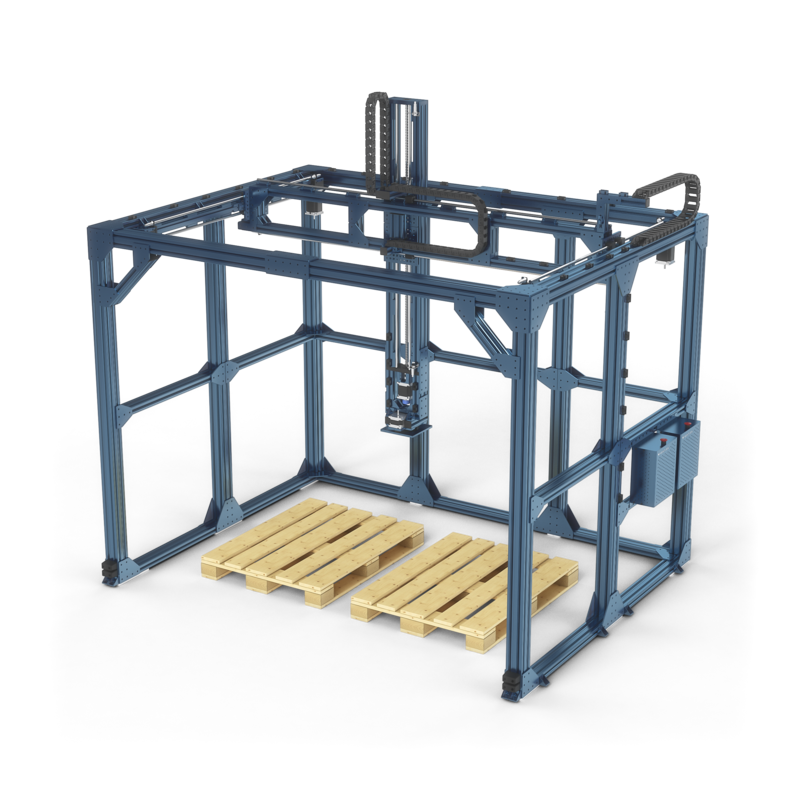

|

There are several application for 4th Axis Palletizer or a Rotary Inspection Station for Universal Robots.

Technical Specifications

Maximum Torque Combinations

Max Torque - Motor and Actuator for Rotary Actuator [Nm] | Max Torque - Motor and Actuator for Heavy Duty Rotary Actuator [Nm] | |

MO-SM-030-0003 | 92 | 187 |

MO-SM-030-0002 | 52 | 116 |

MO-SM-030-0001 | 24 | 55 |

The below figure gives the performance of the Rotary Actuator torque vs speed with all of Vention’s stepper motor combinations driven by MachineMotion AI.

|

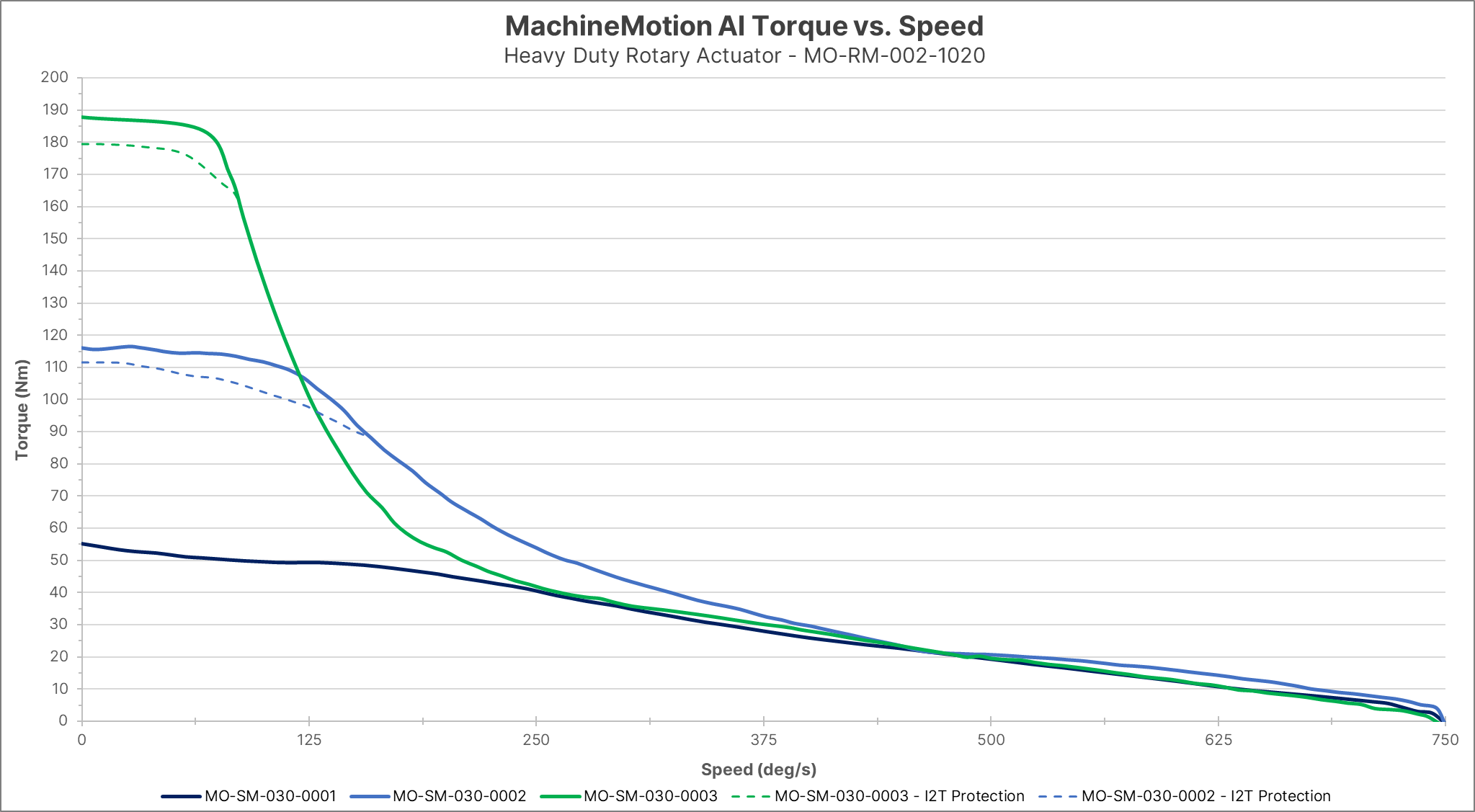

The below figure gives the performance of the Heavy Duty Rotary Actuator torque vs speed with all of Vention’s stepper motor combinations driven by MachineMotion AI.

Specifications

Rotary Actuator | Heavy Duty Rotary Actuator | |

Nominal Backlash [arcmin] | ≤13.6 | <9 |

Nominal Tilting Play [degrees] | ±0.113 | N/A |

Maximum Rotational Velocity [RPM] | 225 (dictated by motor maximum) | 124 (dictated by motor maximum) |

Radial Capacity (Static)*[N] | 1100 | 4100 |

Radial Capacity (Dynamic) [N] | 235 | 4100 |

Axial Capacity (Static)*[N] | 2850 | 5450 |

Axial Capacity (Dynamic) [N] | 2850 | 5450 |

Maximum Tilting Moment (Static)*[Nm] | 275 | 278 |

Maximum Tilting Moment (Dynamic) [Nm] | 0 | N/A |

Motor Compatibility | NEMA 34, 14mm shaft | NEMA 34, 14mm shaft |

Ingress Rating | - | IP65 |

Note*: Assumes low rpm operation (<10 rpm) and only one static force present. For combined loading reach out to application engineering.

Maximum Inertia

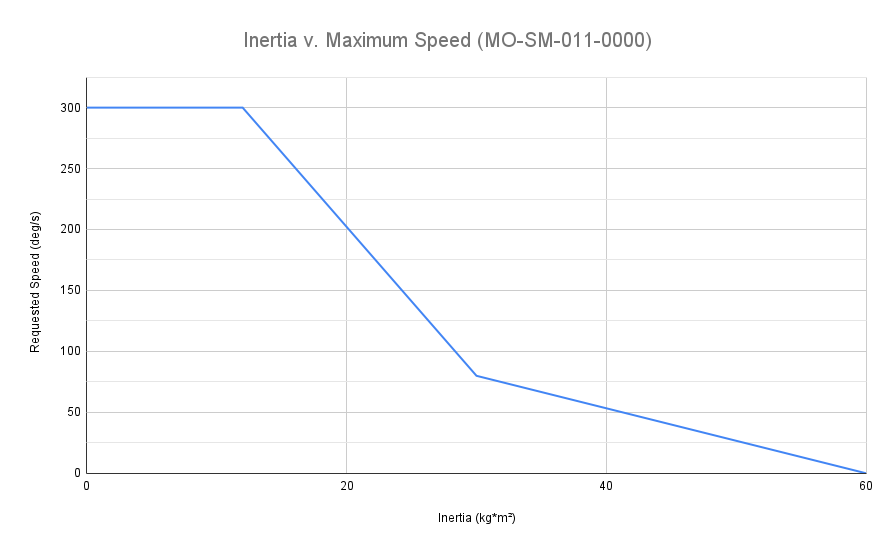

Dimensionally large or heavy assemblies have a lot inertia. Large amounts of driven inertia on the output of the actuator will cause it to function poorly. Generally it is recommended to stay below 20 kg*m² for this actuator. Going above this value decreases the performance of the actuator in two ways. First large oscillations will start to occur near the inputted desired position. Secondly, the actuator will struggle to accelerate and decelerate the load. When large inertias are unavoidable, consult this chart to determine maximum speed.

Maximum speed as a function of inertia. |

Assembly

Motor Mounting

The Rotary Actuator is compatible with all of Vention’s NEMA 34 Stepper Servo motors. The Rotary Actuator is not compatible with any gearboxes.

Installation Procedure: Heavy-Duty Rotary Actuator Motor

To secure the motor shaft to the gearbox, follow these steps:

Access the Internal Coupler: Remove the grub screw from the side of the gearbox using a 4 mm hex key.

Loosen the Clamp: Insert the same hex key through the access hole to loosen the internal clamp screw.

Align the Coupler: Insert a 4 mm hex bit into the access hole. Manually rotate the internal plate until the hex bit aligns perfectly with the socket on the internal coupler screw.

Torque the Connection: Once aligned, tighten the coupler screw to a torque specification of 16.5 Nm.

Final Assembly: Mount the motor onto the gearbox using the screws that came with the motor and replace the grub screw in the access hole to seal the unit.

Notes:

When installing motors, apply a small amount of grease to the motor shaft so that it is lightly coated. This will reduce the possibility of fretting corrosion occurring during operation, making future removal easier.

Moreover, do not use excessive force (hammering, prying or using screws to “push” the motor) to install the motor.

Be sure to tighten the two clamping screws on the input collar behind the plastic covers.

Mounting Sensors

You can add home and end sensors to a rotary actuator, and they will work the same way as home and end sensors on a linear actuator.

A home position sensor enables repeatable motion: it provides a reference point to which the actuator can “zero.” Adding both home and end position sensors means that in addition to enabling repeatable motion, you can also limit the actuator’s travel.

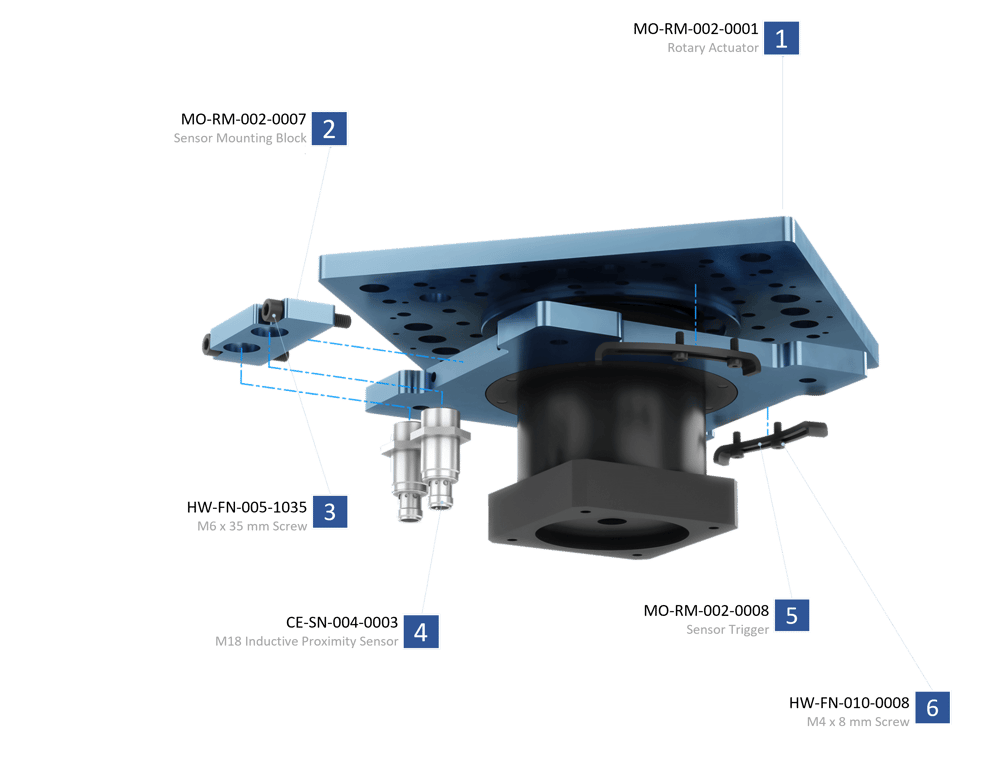

The home and position sensors are both inductive proximity sensors (CE-SN-004-0003). They are each mounted to a block (MO-RM-002-0007), which is itself mounted to the rotary actuator with two M6 x 35-mm screws (HW-FN-005-1035).

The sensors are activated when they approach a trigger. Two triggers—one for each sensor—are typically mounted to the underside of the top plate. Each trigger is mounted through a slot, which allows its position to be fine-tuned, with two M4 x 8-mm screws (HW-FN-010-0008).

Rotary actuator sensor mounting |

.png)