|

Overview

This document outlines the steps necessary to set up and program a Fanuc CRX robot in MachineLogic. By following this guide, you’ll be able to seamlessly integrate your Fanuc robot with Vention’s motion components ecosystem using MachineMotion AI.

Compatibility Notice

This user guide is compatible for MachineMotion AI only. To access the guide for the previous MachineMotion v2, follow the following link: MachineMotion v2 - Fanuc Configuration Guide

Supported Models

CRX-5iA

CRX-10iA

CRX-10i/L

CRX-20iA/L

CRX-25iA

Required Software and Hardware

Software Option

Remote Motion Interface (R912) — PR-FA-002-0022

Enables remote control capabilities between MachineLogic and the Fanuc controller.Advanced DCS Package (R859)

The Advanced DCS Package includes safety options and the powerful 4D Graphics option.

Hardware Option

CRX Safe I/O — PR-FA-002-0021

Integrates safety signals with the Fanuc robot.

Installation Steps

System Connection

To program a Fanuc CRX series Robot with MachineMotion AI, ensure you have the following components:

✅ MachineMotion AI Controller

✅ Pendant V3

✅ Robot Safety Module

✅ E-Stop Module with Reset

✅ Fanuc Robot with controller

✅ Safety Extension Cables

Note: This list depicts the minimum set of components needed to configure and control your Fanuc robot with MachineMotion AI.

Your system may have a different set of components according to your safety needs.

.png) Figure 1. Safety Components Connection |

Safety Wiring

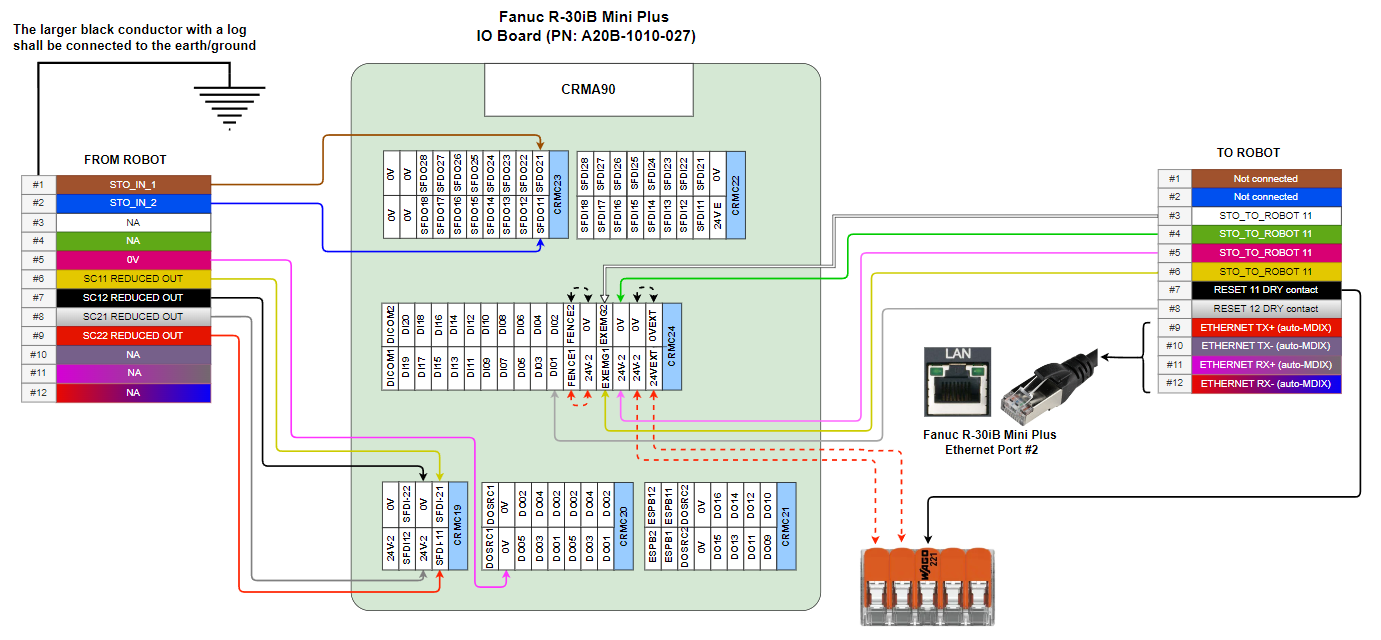

Vention’s Robot Safety Module is used to interface safety signals and Ethernet connection to the FANUC controller. Please follow the Automation System Diagram (ASD) made by your Application Engineer, or one of the diagrams in the Robot Safety Module AI Datasheet.

Safety behaviour

In case of an E-stop (Vention or FANUC Pendant), or any other device that detects a dangerous situation on the Vention Safety Chain:

Safe Behaviour:

MachineMotion axis falls into STO.

FANUC CRX Falls into STO or SS1, as configured.

Recovery

Pressing on the reset (blue) button will give power back to the MachineMotion and activate FANUC CRX safety signals from Robot Safety Module.

In case of a reduced speed situation from the laser area scanner:

Safe Behaviour:

FANUC CRX will activate collision detection and slow down to collaborative speed.

MachineMotion is not influenced by this situation. This needs to be taken into account in the risk assessment. Axis will run at configured speed.

Recovery:

If the laser area scanner is not able to detect a human everywhere where there is a danger, but can detect the entry points, then the laser scanner should be configured with manual reset. In this case, pressing the reset button will bring back the FANUC CRX to normal speed.

If the laser scanner is able to detect a human everywhere where there is a danger, then the laser area scanner can be configured with an Auto-Reset Safety Module AI (to be determined and confirmed by risk assessment). In this case, if the laser area scanner does not detect a human in the workspace anymore, the FANUC CRX will resume to full speed.

Robot Controller Safety Wiring Diagram

Important: Ethernet Cable Connection

To ensure proper functionality, the ethernet cable needs to be connected to the port#2 in the Fanuc controller as shown in the following picture.

1. Download Deployment Files

Download and extract the deployment zip file from:

You should get:FanucConfig_Step1FanucConfig_Step2FanucConfig_Step3

2. Configure Controller

2.1 Initial Setup

This step prepares the Fanuc controller in order to set each variable automatically in the following steps.

Power on the robot controller

Insert USB drive in the robot controller (not the Teach Pendant).

Open the virtual iPendant via the icon at the bottom right

.png)

Navigate:

MENU → 7 FILE → F5 [UTIL] → 1 SET DEVICE → 6 USB DISK (UD1:)Open

FanucConfig_Step1folderLoad files:

FANUC.CVRGET_PARAMS.TPRMI_Move.TP

Action

Go to each file → Press

F3 [LOAD]→ Confirm withYESOverwrite if prompted.

Restart the Controller:

Make sure to be in Teach Pendant mode (see the icon at the top right of the screen)

Navigate:

FCTN → 0 NEXT → 8 START MODE → CTRLPower off → Wait 10 sec → Power on

Override Settings

Navigate:

MENU → 4 VariablesUpdate:

$PLST_SCHNUM→256Tip: to scroll fast via the touch screen, you can press the empty space below the list

Navigate:

MENU → 0 NEXT → 1 Program Setup → Numeric RegistersSet value:

256

Cold Restart:

FCTN → Start (COLD)

2.2 I/O and Controller Configuration

2.2.1 Load Configuration Files

Open iPendant

Navigate:

MENU → 7 FILE → UTIL → SET DEVICE → USB DISK (UD1:) → FanucConfig_Step2Load files:

FANUC.XVRDIOCFGSV.IO

Action

Go to each file → Press

F3 [LOAD]→ Confirm withYESOverwrite if prompted.

2.2.2 Apply DCS (Dual Check Safety)

Navigate:

MENU → 0 NEXT → 6 SYSTEM → F1 [TYPE] → 7 DCSSelect:

F2 [APPLY]Code:

1111Confirm.

Navigate:

FCTN → 0 NEXT → 8 START MODE → CTRLPower off → Wait 10 sec → Power on

2.3 Payload Creation

Navigate to:

MENU → 7 FILE → FanucConfig_Step3Load:

SET_PAYLOADS.TPExecute the program:

Select

SET_PAYLOADSEnable the teach pendant

Press Play

Hold Run toggle in FWD until completion

You may see an alarm: SYST-212 Need to apply to DCS param.

Re-apply DCS as shown in Step 2.

Connecting to the Robot Controller from MachineMotion

You're now ready to deploy your MachineLogic application from your Vention project to the MachineMotion AI controller!

Follow the steps detailed in the Deploy your Application and Configuration to Controller documentation.

Support

If you need further assistance, reach out to our support team:

📧 support@vention.io

📞 +1-800-940-3617 (ext. 2)

Additional Information

Manual - IO Configuration

To access IO configuration on the Fanuc controller:

MENU → 5 I/O → [TYPE] → Select the type you wish to access from the list (UOP or Digital)

Select Config and then configure it as shown bellow.

UOP Configuration - Outputs

UOP Configuration - Inputs

Digital Configuration - Outputs

Digital Configuration - Inputs

Manual - Controller and Collaborative Robot Configuration

Controller Reset Configuration

[MENU]→ 0 [NEXT] → 6 [SYSTEM] → [TYPE] -> 6 Config

Go to Line 7: Enable Ui Signal -> Select -> TRUE

Network Configuration

[MENU]→ 6 [SETUP] → [TYPE] → 0 [NEXT] -> 6 [Host Comm]

Select 1 [TCP/IP] and then [DETAIL].

Ensure Line 2 indicates Port #2.

If Line 2 indicates Port #1, select [PORT].

Configure the IP settings for Port #2:

IP Address: 192.168.5.3

Subnet Mask: 255.255.255.0

Router IP Address: 192.168.5.1

Make sure the Port #1 is not in the same subnet as port #2 to ensure no network conflict problems will occur.

Collaborative Robot Configuration

Initiate the Safe I/O card

[MENU]→ 0 [NEXT] → 6 [SYSTEM] → 7 [DCS]

Safe I/O device (Line 16) and Enter

Init two times

[PREV]

Go to 7. Cart. Speed check , Enter

Select No. 1 -> Detail

2. Enable/Disable -> Choice -> Enable

7 Limit: Set Value to 250

8 Stop type -> Choice -> Not Stop

9 Speed Control -> Choice -> Cart Speed

11 Disabling Input -> Choice -> SPI -> [1:SFDI1]

[PREV]

Select No. 2 -> Detail

2. Enable/Disable -> Choice -> Enable

7. Limit: Set Value to 250

11 Delay time -> Set Value to 500 ms

12 Disabling Input -> Choice -> SPI -> [1:SFDI1]

Return to the DCS main page and select Safe I/O Connect

SIR[1] =! CSC[2] - - - [0] OK

@SPO[9]= SSI[10] AND! SIR[2] OK

Return to the DCS main page and select Collaborative robot then ENTER

Line 4 External Force Limit / Disabling input -> Limit 1: 150N -> SIR[1]

Force Limit Sensitivity: LOW

Line 33 Set collaborative speed to the desired value (Default is 250

Line 35 Disabling Input F [20]

Line 37 Define Max Speed to 2000 mm/s

Line 43 STOP -> Choice -> SIR [2] -> Enter

Line 68 Manual Guided Teaching -> Enter

Activation input -> Choice -> DI -> Set value to 2

Backup and Restore

Backup Steps

On teach pendant:

FCTN → Abort AllMENU → 7 FILE → UTIL → Set Device → USB DISK (UD1:)Create directory via

UTIL → Make DIRNavigate into directory

Select

8 All of Above → YES

Restore Steps

Insert a USB stick with your MD backup

Perform a Controlled Start:

Cycle power

Hold PREV + NEXT

Enter

3 → ENTER

Navigate:

MENU → File → F5 [UTIL] → Set DeviceAccess backup folder

Select Restore Type:

System files, TP programs, Application, etc.

Or choose

All of above

Confirm and start the restore:

Press

F4 YES

Perform Cold Start

FCTN → Start (COLD)

MachineMotion v2 Previous Documentation

MachineMotionv2 - Fanuc Configuration Document

Configuration Files for MachineMotion v2: Download

.png)