Introduction

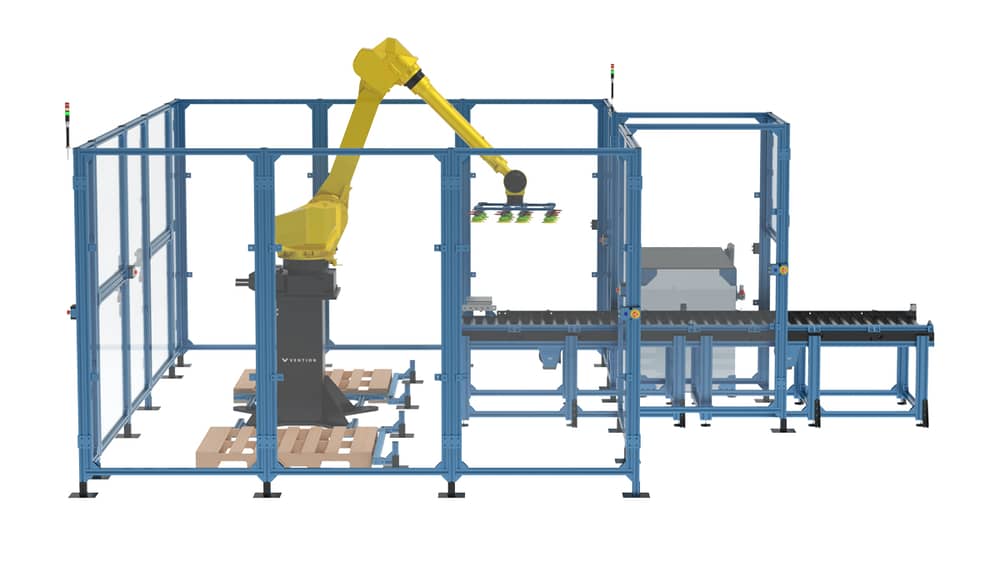

As Vention enters the world of industrial robot palletizing applications, we sought it necessary to launch this effort alongside an array of end-of-arm tooling options to ensure you, the user, can make an informed choice to meet the needs of your application.

At the core of these gripper offerings is a structure designed using Vention’s durable modular hardware. This leads to quicker development cycles for new grippers and also permits for easier resizing of current gripper designs to accommodate different application SKU requirements.

Below you can find the current offerings for industrial palletizing, of which will continue to expand as we meet the needs of new application developments. Feel free to head over to our public design page to explore turnkey palletizer applications as well.

|

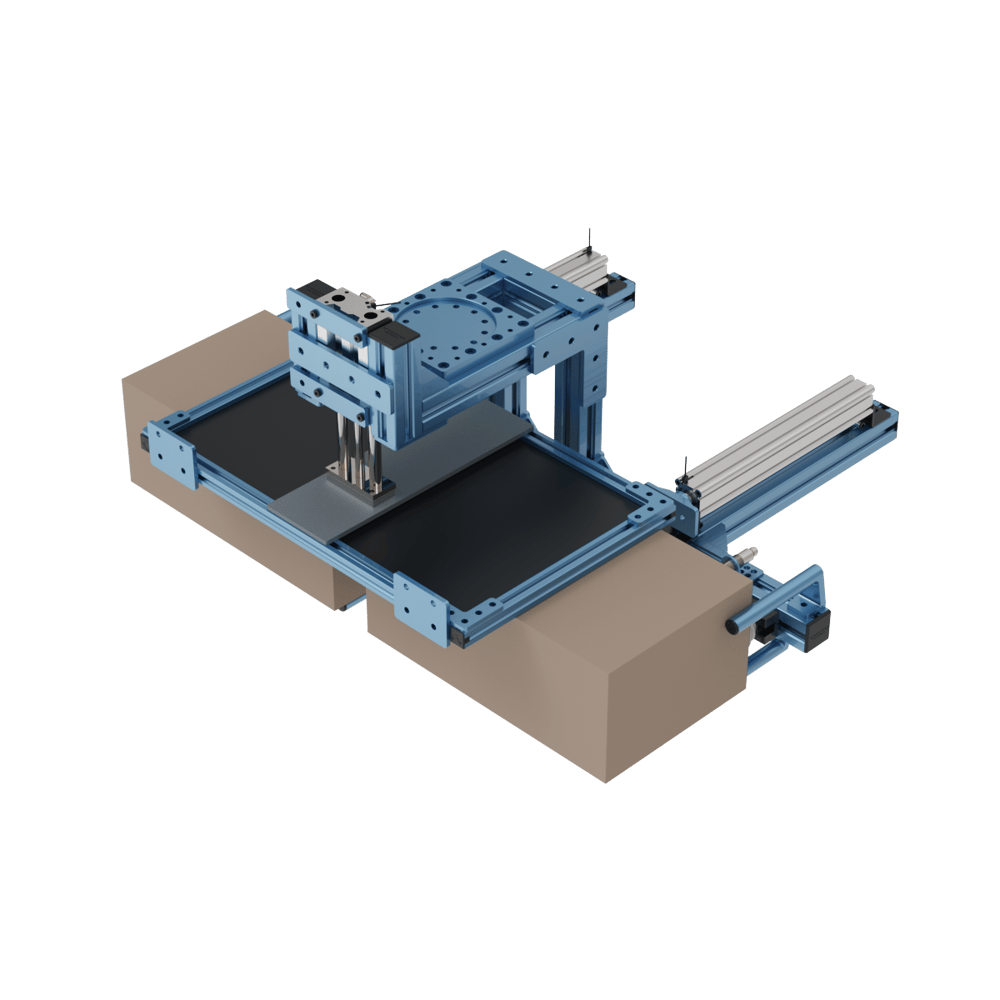

Fork-Style Gripper

This gripper was developed for scenarios where products to be palletized cannot be gripped from the top with a vacuum-style gripper. Products include open-top boxes, trays, and possibly bags that do not fall within the Industrial Bag Gripper envelope.

This modular gripper operates by picking a product on a roller conveyor along the axis of the rollers and holds it in place using suction and a top guided cylinder with retaining plate. Once arrived at the place position, the suction and guided cylinder will release, allowing for the 2 rear-mounted and speed-regulated pneumatic cylinders to release the product from the gripper onto the pallet.

|

|

Technical Specifications

The following table provides a list of operating specifications for the Fork-Style Gripper:

Specification | Value |

|---|---|

Max payload (kg) | 30 |

Number of products per pick | 1-3 |

Gripper pick/drop time (s) | 0.5-1.5 |

Maximum SKU size (mm) | 900L x 500W x 500H |

Minimum SKU size (mm) | 200L x 150W x 150H |

Recommended operating pressure (MPa) | 0.70 |

Feedback sensors included | Pick detection, pneumatic cylinder state |

If these specifications do not meet the requirements of your application, feel free to reach out to our application engineers to help further investigate its feasibility.

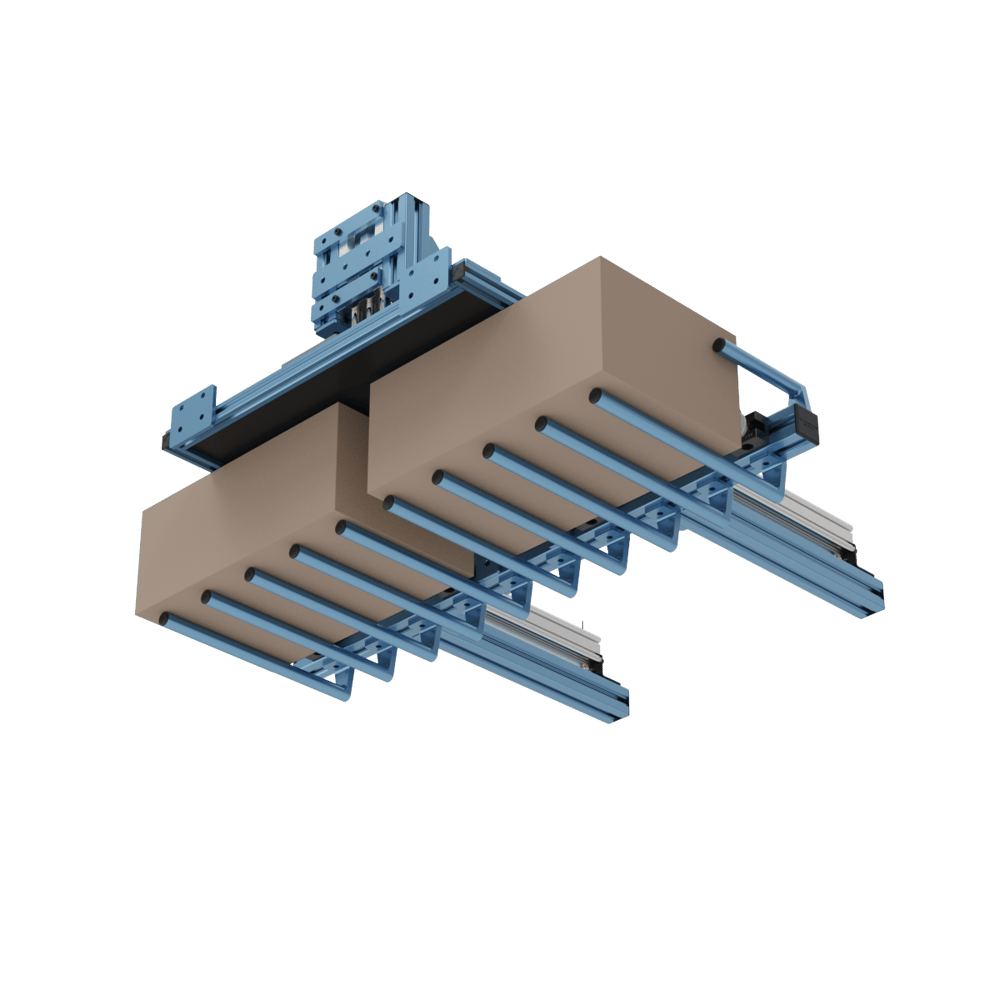

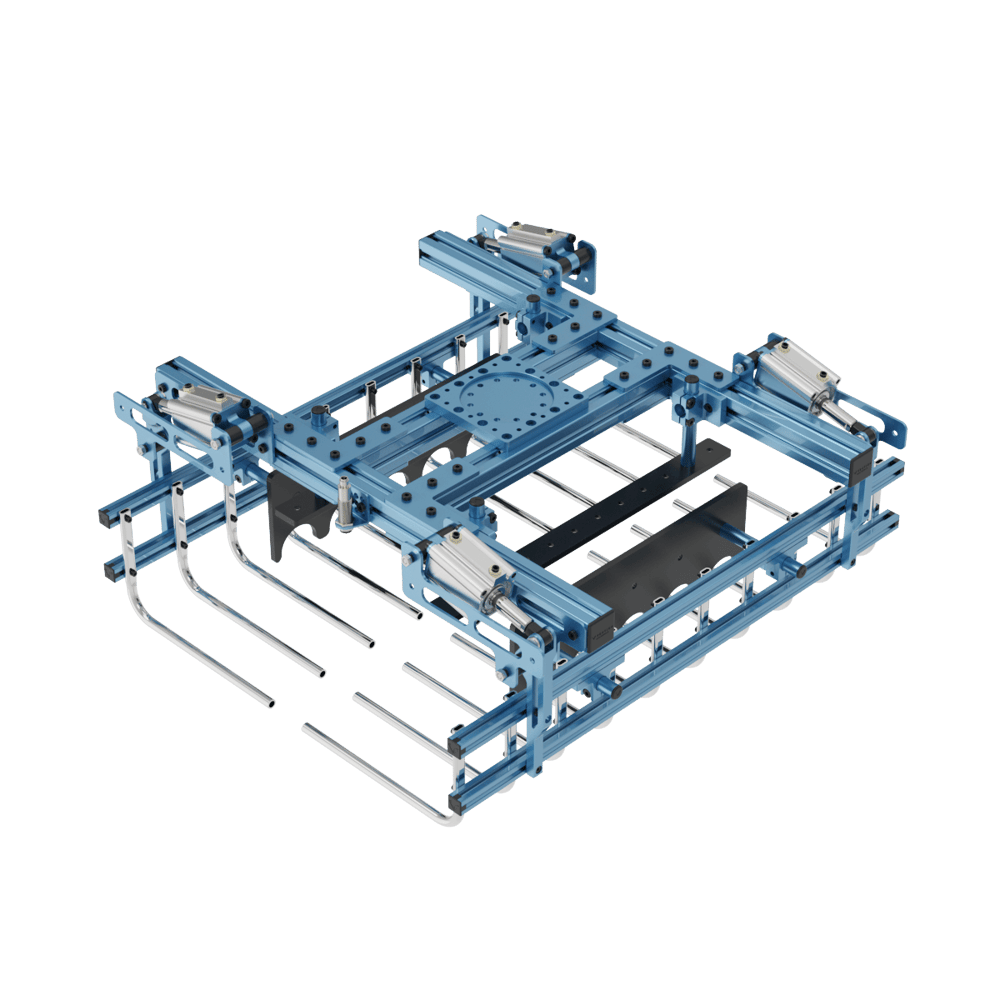

Industrial Bag Gripper

As the name suggests, this gripper aims to pick bags from roller conveyors and palletize them. This product focuses on modularity to accommodate a large range of bag SKUs. This gripper can handle materials that are unreliable or impossible to grasp using suction. Its strength-to-weight ratio offers an excellent alternative to conventional vacuum and suction-cup grippers.

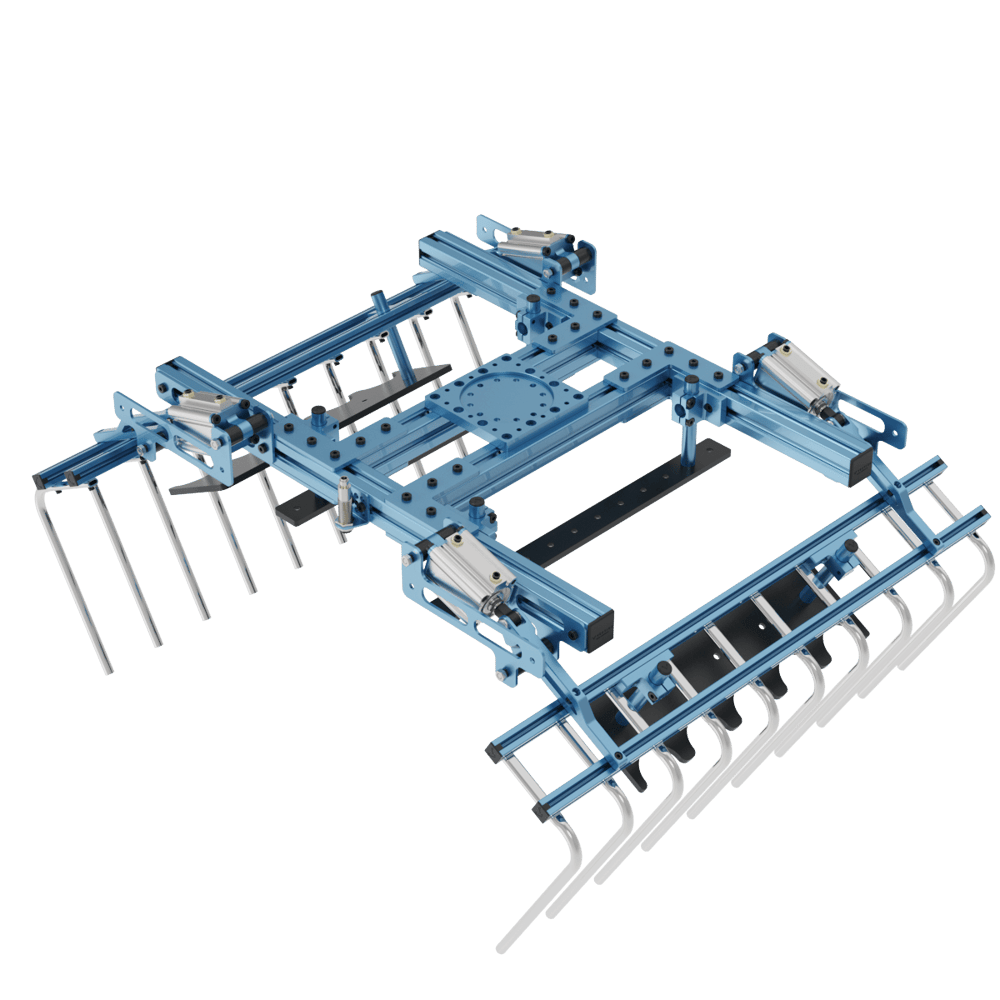

This grippers operates by using a set of 4 pneumatic pistons to pivot a sub-assembly of metal fingers in order to pick and place bags from a roller conveyor. As an optional feature, side and top guards can be added to manually adjust the size of the bag that the gripper can handle (to be used in applications where multiple SKUs are present). Lastly, to ensure proper operation of the gripper, an NPN diffuse sensor (for bag detection) and two NPN pneumatic actuator position sensors (for gripper state assessment) are included.

|

|

Technical Specifications

The following table provides a list of operating specifications for the Industrial Bag Gripper:

Specification | Value |

|---|---|

Max payload (kg) | 30 |

Gripper pick/drop time (s) | 0.5-1 |

Recommended operating pressure (MPa) | 0.60 |

Maximum SKU size (mm) | 610W x 915L x 205H |

Minimum SKU size (mm) | 205W x 305L x 125H |

Finger pitch (mm) | 90 |

Feedback sensors included | Pick detection, pneumatic cylinder state |

If these specifications do not meet the requirements of your application, feel free to reach out to our application engineers to help