|

|---|

Overview

Vention offers a range of motors that are compatible with the MachineMotion AI controller. Depending on your application and technical requirements, compare the specifications of each motor below.

This document covers requirements for current version of MachineMotion controller. For previous version, refer to link below:

MachineMotion AI Motors

|

|

| |

Name | |||

Part Number | MO-SM-030-0003 | MO-SM-030-0002 | MO-SM-030-0001 |

Included cable | 5-meter signal-power hybrid cable | 5-meter signal-power hybrid cable | 5-meter signal-power hybrid cable |

Motor Type | Hybrid Stepper Servo | Hybrid Stepper Servo | Hybrid Stepper Servo |

Motor Flange | NEMA 34 | NEMA 34 | NEMA 34 |

Motor Length | 157 mm | 96 mm | 66.5 mm |

Step Angle | 1.8° ± 5% | 1.8° ± 5% | 1.8° ± 5% |

Holding Torque | 13 Nm | 7.2 Nm | 4 Nm |

Output shaft | 14 mm | 14 mm | 14 mm |

Input Voltage (Motion) | 60-80V, 72V nominal | 60-80V, 72V nominal | 60-80V, 72V nominal |

Maximum Input Current (Motion) | 5A | 5A | 5A |

Maximum Motor Phase Current | 10A RMS | 10A RMS | 10A RMS |

Maximum Mechanical Power (Torque x Speed) | 260W | 260W | 240W |

Input Voltage (Drive Logic) | 20-28V, 24V nominal | 20-28V, 24V nominal | 20-28V, 24V nominal |

Maximum Input Current (Drive Logic) | 0.2A | 0.2A | 0.2A |

Communication Protocol | CANopen over EtherCAT (CoE) | CANopen over EtherCAT (CoE) | CANopen over EtherCAT (CoE) |

Power-Signal ports (IN/OUT) | Amphenol Sine Systems ecomate® RM Hybrid connector (3 power pins, 10 signal pins) | Amphenol Sine Systems ecomate® RM Hybrid connector (3 power pins, 10 signal pins) | Amphenol Sine Systems ecomate® RM Hybrid connector (3 power pins, 10 signal pins) |

Home/End sensor ports (A/B) | M12 A-coded female | M12 A-coded female | M12 A-coded female |

Brake port | M12 D-coded female | M12 D-coded female | M12 D-coded female |

Operating Temperature | 0℃ to + 40℃ | 0℃ to + 40℃ | 0℃ to + 40℃ |

Relative Humidity | 0% -85% RH, non-condensing, non-splash | 0% -85% RH, non-condensing, non-splash | 0% -85% RH, non-condensing, non-splash |

Vibration | IEC 60068-2-6

| IEC 60068-2-6

| IEC 60068-2-6

|

Shock | IEC 60068-2-27

| IEC 60068-2-27

| IEC 60068-2-27

|

Motor Insulation Class | B | B | B |

Motor Insulation Resistance | 100 Mohm | 100 Mohm | 100 Mohm |

Housing Material | Steel (motor) and aluminum (junction box) | Steel (motor) and aluminum (junction box) | Steel (motor) and aluminum (junction box) |

Overall Width | 86 mm | 86 mm | 86 mm |

Overall Length | 258 mm | 198 mm | 168 mm |

Overall Height | 103 mm | 103 mm | 103 mm |

Weight | 6.37 kg | 4.53 kg | 3.43 kg |

Certifications | cETL,

EU DoC,

FCC, ISED

| cETL,

EU DoC,

FCC, ISED

| cETL,

EU DoC,

FCC, ISED

|

Safety data - EN ISO 13849-1 | PLe / Cat3 MTTFd : 337 years DCavg : Medium PFHd : 4.29E-08 | PLe / Cat3 MTTFd : 337 years DCavg : Medium PFHd : 4.29E-08 | PLe / Cat3 MTTFd : 337 years DCavg : Medium] PFHd : 4.29E-08 |

Compatibility |

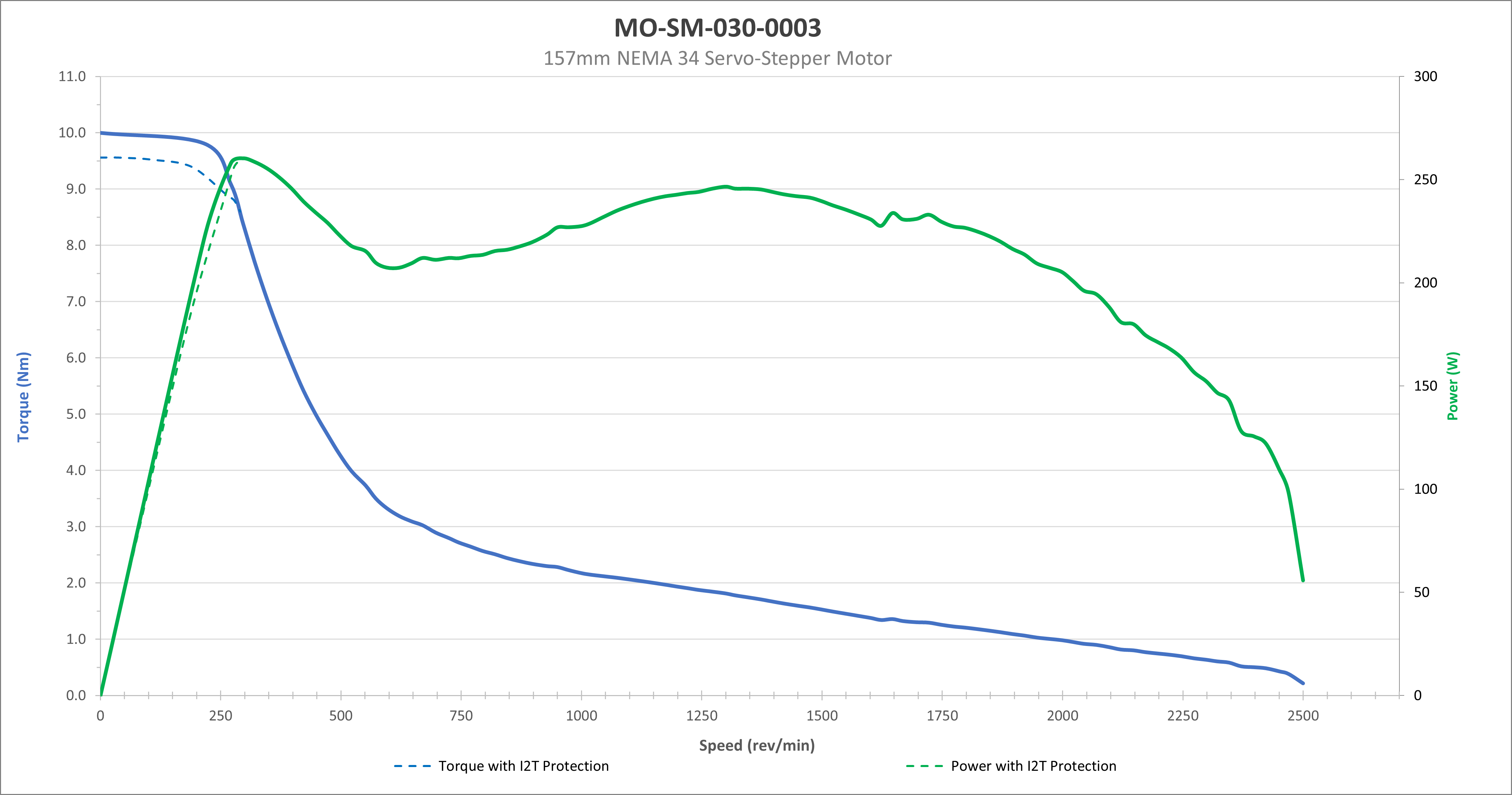

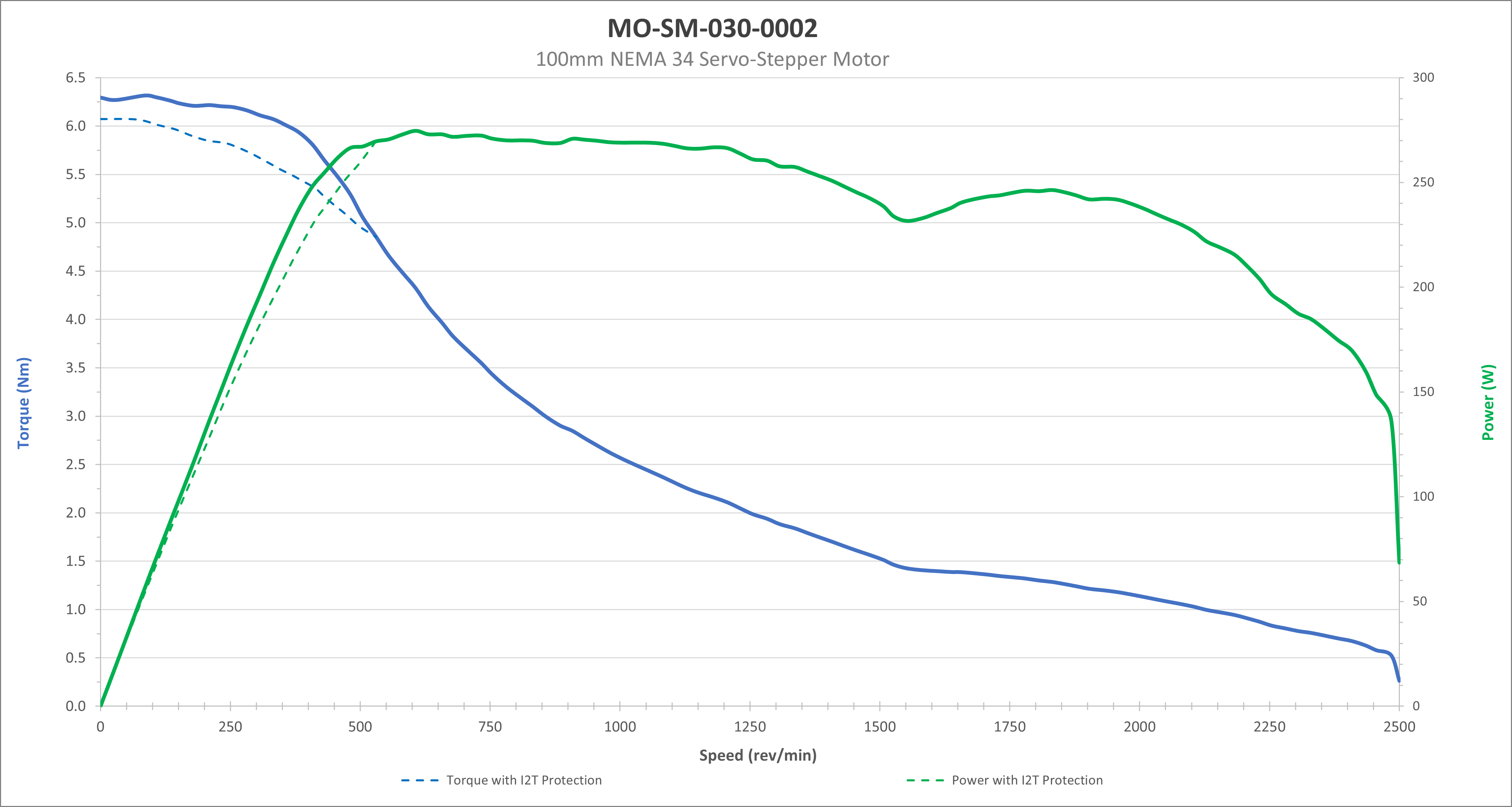

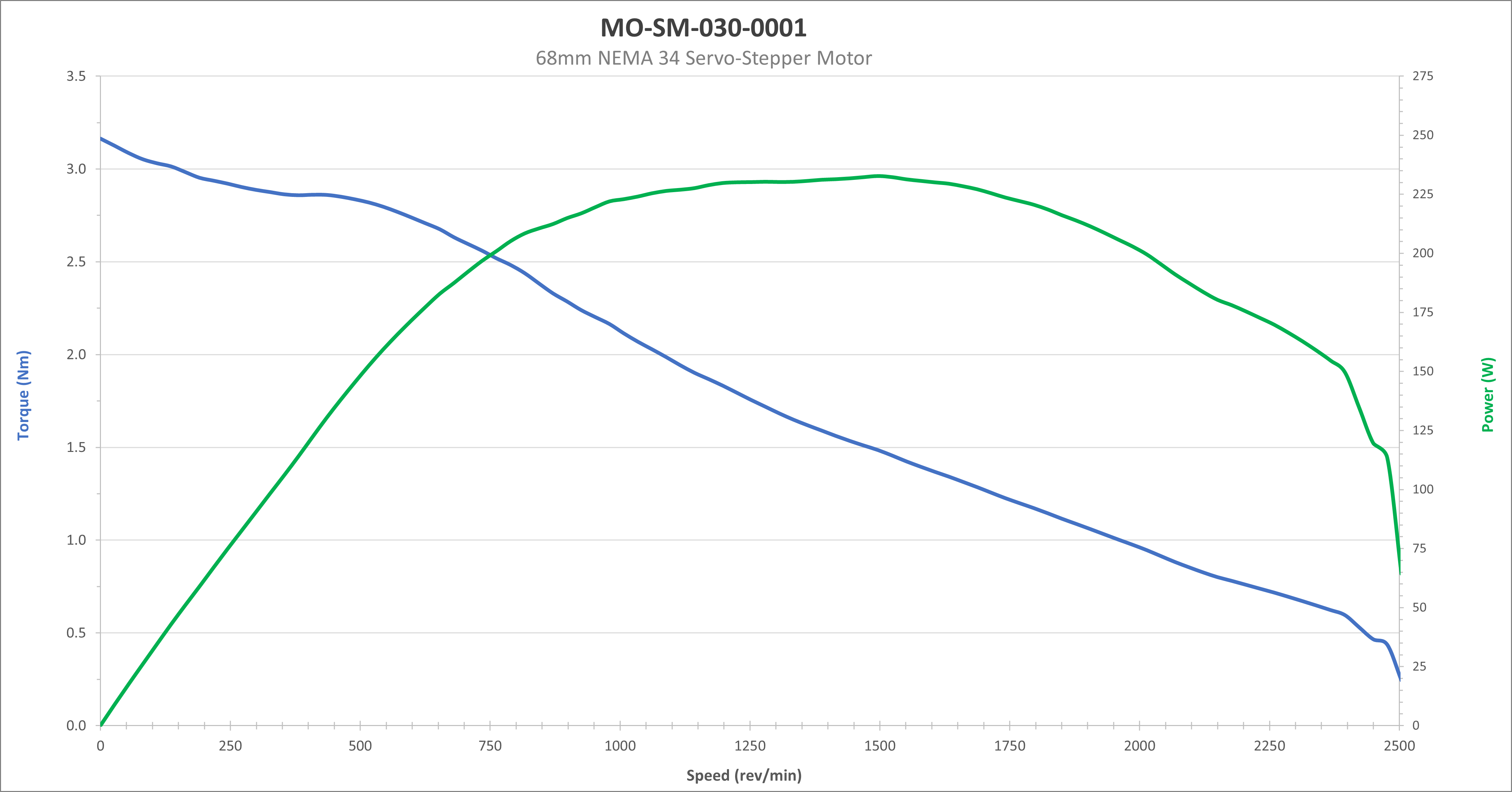

Motor torque-speed curves

|

|

|

Motor Daisy Chaining Guidelines

|

|---|

When motors are being daisy chained, your system will experience a voltage drop on each motor cable that corresponds to the overall current draw of the downstream motors. The motor drive will operate correctly as long as its motion supply voltage stays above 60V when no brake is used. When a brake is used, the motion supply voltage must remain above 67V. It is essential to recognize that the actual voltage can vary over time due to the instantaneous current draw of the motors. Additionally, it is crucial to limit the total cable length and the distance between motors to facilitate reliable EtherCAT communication and maintain the drive logic supply voltage above an acceptable level. Therefore, please ensure compliance with the following daisy chaining guidelines.

Voltage Requirements

If a motor does not have a brake, make sure it gets at least 60V.

If a motor has a brake, it needs at least 67V.

Cable, Motor & Brake Limitations

The cable between any two motors shouldn't be longer than 50 meters.

The total length of all the cables in one chain shouldn’t go over 100 meters.

You can connect up to 10 motors in one daisy chain.

If one of your motors has a brake, it should be no farther than the 6th motor in the chain.

For daisy chained applications requiring more than 20 motors, the addition of a power supply (CE-PS-024-0094) and a cable (CE-CA-043-5000) is required

Motor connector pinouts

Pin | IN | OUT |

|---|---|---|

A | Motion supply 0V | Motion supply 0V |

B | Protective Earth | Protective Earth |

C | Motion supply 72V | Motion supply 72V |

1 | Drive logic supply 24V | Drive logic supply 24V |

2 | Drive logic supply 0V | Drive logic supply 0V |

3 | Safe Torque Off A (OSSD) | Safe Torque Off A (OSSD) |

4 | Safe Torque Off B (OSSD) | Safe Torque Off B (OSSD) |

5 | EtherCAT In TX+ | EtherCAT Out TX+ |

6 | EtherCAT In TX- | EtherCAT Out TX- |

7 | EtherCAT In RX+ | EtherCAT Out RX+ |

8 | EtherCAT In RX- | EtherCAT Out RX- |

9 | Reserved | Reserved |

10 | Reserved | Reserved |

Pin | A | BRAKE | B |

|---|---|---|---|

1 | Sensor supply output 24V (3A max) | Brake supply output 72V (0.5A max) | Sensor supply output 24V (3A max) |

2 | Normally closed NPN sensor input | Brake detection 1 | Normally closed NPN sensor input |

3 | Sensor supply output 0V (3A max) | Brake detection 2 | Sensor supply output 0V (3A max) |

4 | Not connected | Brake supply output 0V (0.5A max) | Not connected |

Power-Off Brake

| |

Name | |

Part Number | MO-PT-006-0001 |

Holding Torque | 9 Nm |

Rated Current | 0.25 A |

Rated Voltage | 72 V DC ± 7% |

Rated Power | 18 W |

Engagement Time | 7 ms |

Connector | M12 D-coded Male |

Brake Type | Power-off, permanent magnet |

Shaft Diameter | 14 mm |

Bore Diameter | 14 mm |

Max speed | 4 000 rpm |

Moment of inertia | 1.0711 X 10-5 Kg m2 |

Dimensions | 85 mm x 85 mm x 100.5 mm |

Weight | 1.527 kg |

Operation details

The power-off brake is controller by a 72VDC supply. When the brake is de-energized, the brake shaft is locked. When the brake is energized, the brake shaft can rotate freely. The brake will be automatically locked if either one of these conditions is true:

The MachineMotion AI controller is in emergency stop.

The motor drive connected to the brake is not in operational state.

Pin | Description |

|---|---|

1 | Brake supply input 72V |

2 | Brake detection 1 |

3 | Brake detection 2 |

4 | Brake supply input 0V |

.png)

.png)